2017 HEAVY COMMERCIAL - 1st RUNNER UP

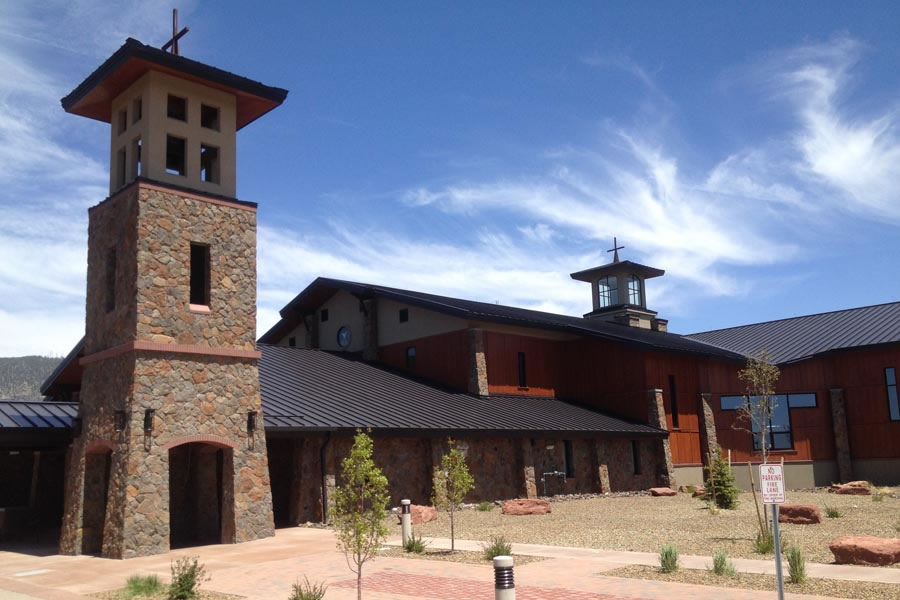

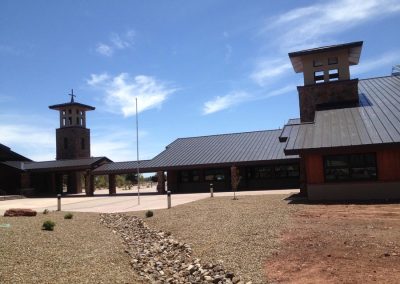

The San Francisco de Asis Church in Flagstaff, Arizona, is the latest ICF project completed for the Phoenix Archdiocese of the Catholic Church.

With soaring ICF gables and an elegantly sloped bell tower, it is truly a landmark project for the region. “There is no building in northern Arizona that utilizes the ICF concept as this project has,” says Rick Chalupnik, a project manager at ICF Specialist who supervised the install. The building is named after St. Francis of Assisi.

The archdiocese has built almost two dozen schools, churches, and administrative buildings with ICFs over the past decade with good results. The decision to use that technology for this project was simple.

The church is laid out in the traditional cruciform shape, with a broad nave to accommodate the congregation. As the church was nearing completion, the construction team moved on to the second phase of the project, a K-12 private school adjacent to the worship facility. Together, the two buildings comprise 90,000 sq. ft., and used just more than 50,000 sq. ft. of Fox Block ICF.

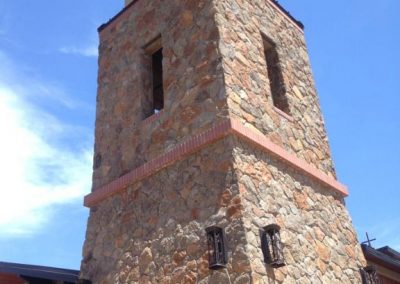

The ICF installers faced several daunting challenges, which they solved with ingenuity and craftsmanship. Gables on the church and school reach 40′ high without intervening floors, and the walls included several large, unusually shaped window openings, which were bucked and reinforced with lumber.

The walls would need to be stacked and braced significantly off plumb—about six inches in four feet on the lower section.

Chalupnik says “The sloped walls were poured by tilting all of the bracing to a calculated degree in order to make all four corners line up consistently through the 40’ height.”

Because of the slant, pre-manufactured corners could not be used. Every corner was custom cut to fit and then reinforced. He says, “It’s not the first time sloped walls have been done, but it’s still impressive.”

Due to budgeting, the project needed to be phased, and Flagstaff, located in the mountains of Northern Arizona, has an elevation of nearly 7,000 feet. As the project extended through several winters, some of the ICF work took place in temperatures well below freezing. The church and administrative buildings were completed early in 2016, with the final phase of the school wrapping up in November of 2016.

The builder notes the project was completed on time “with a level of quality that exceeded expectations, particularly considering the weather conditions.”

The priest and parishioners alike are extremely pleased with the final result.

Chalupnik says, “The beauty of the architecture is second to none in the northern Arizona area. Using an ICF system will allow for the structure to last for well over a century with little if any maintenance of the core structure.”

Project Statistics

Location: Flagstaff, Ariz.

Type: Catholic Church and School

Size: 90,000 sq. ft. (floor)

ICF Use: 50,610 sq. ft.

Cost: $16 million

Total Construction: 2.5 years

ICF Installation time: 180 days

Construction Team

Owner: Phoenix Archdiocese

General Contractor: BED Southwest

ICF Installer + Form Distributor: ICF Specialist

Architect + Engineer: Brent Maupin Eng. and Design

ICF System: Fox Blocks

Fast Facts

Gables to 40’ high

Tower poured with sloped ICF walls

Landmark project for region