No matter where the jobsite is located, regardless of whether it’s residential or commercial, every structure needs to “meet code.”

In the United States and Canada, there are a dozen or more building codes, which specify the minimum acceptable building standards in that particular jurisdiction. These codes are enforced by building inspectors and other officials to ensure the construction is safe and durable.

Like every building material, insulated concrete forms (ICFs) can be certified, or code-approved, to aid these officials in their evaluations.

Despite the many codes covering North America, the vast majority of new construction is based on two sets of codes.

In Canada, nearly all construction is governed by the National Building Code of Canada (NBC). Testing is done at the Canadian Construction Materials Centre (CCMC), which issues the evaluation reports.

In the United States, the International Code Council (ICC) oversees the most prevalent building code, with evaluation reports being issued by ICC Evaluation Services (ICC-ES)

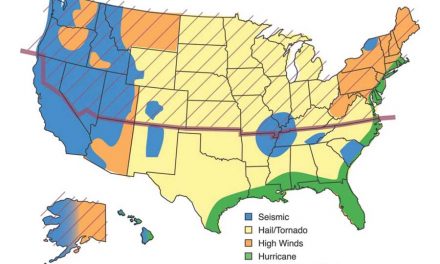

Several states have their own codes, usually based on the ICC, and modified to fit their regional needs, such as fire resistance in California, insulation requirements in Wisconsin and New York, or better wind resistance in Florida.

Several cities, including New York City and Los Angeles, have their own requirements; the building code in Miami-Dade County, Fla., is considered to be among the most stringent in the world.

“Some states specify the code revision—2000, 2003, or 2006—and others tweak that code to meet specific criteria or building concerns within their state,” explains Tom Patton, technical director at Arxx Building Products.

Final approval of whether a product is an acceptable building material or not, surprisingly, doesn’t rest with ICC-ES or corresponding testing agencies. According to a 2005 White Paper published by the ICC, “it is the decision solely of the Authority Having Jurisdiction (AHJ), in most instances represented by the code official.”

“The building code sets minimum requirements for life safety and preservation of property…It also gives the AHJ the latitude to allow materials and methods of construction that are not addressed in the code,” the paper continues. “The official can perform his own analysis of evidence presented or can rely on independent, qualified sources that do the analysis and provide their findings.”

Specifically as it relates to ICFs, code officials are primarily concerned about three things: fire resistance, structural integrity, and insulation value. An evaluation report, issued by ICC-ES, CCMC or other qualified body, makes this task much easier. So while certification isn’t absolutely necessary, it is very useful for determining whether the material meets the minimum requirements. The chart on the next page summarizes manufacturers’ claims regarding their code approvals.

ICC evaluation reports are valid only for the specific products and manufacturing facilities tested, a fact which a few companies in this industry have tried to gloss over. The problem is so rampant that last year ICC Evaluation Service, Inc. published a public notice to set the record straight.

“ICC-ES is aware that, currently, there are many ICF manufacturers producing product in plants not recognized in their evaluations reports,” states the report. “These manufacturers cannot, under ICC-ES rules, use their ICC-ES evaluation reports in conjunction with such product. If a manufacturing plant is not ‘listed’ in a report, its product is not recognized by ICC-ES as being in compliance with applicable codes. It is important that code officials and building professionals be aware of this fact, and be on the lookout for false or misleading claims of ‘code compliance’ for non-recognized products.”

Reward Wall Systems is one company that has been conspicuous in their adherence to ICC rules. “As evident by our compliance history, Reward has always felt it critical to be in line with ICC-ES rules even though some of our competitors are trying to cut costs by cutting corners and using their ICC-ES evaluation reports in improper ways,” reads one press release on the issue. “Because this is such a critical issue for ICF manufacturers and their distributors, we expect to see this issue to continue to receive a greater emphasis well into the future.”

The complete text of the ICC-ES public notice is available online at www.icc-es.org/News/ICF_public_notice.pdf.

So how can an inspector, code official, or interested builder tell if their ICF is truly code-approved?

First, determine what building code is enforced in your jurisdiction, and which testing agency that code body uses.

Then contact the building code testing agency (usually ICC-ES or CCMC) and ask for a copy of the code certification. Usually these certificates can be viewed online.

With ICC-approved products, it’s often as easy as checking the label. Each approved product has labeling requirements to help officials match the product to an evaluation report. The label includes the manufacturer’s name, the product name, Evaluation report number, and name of inspection agency when required. Sometimes it’s accompanied by an italic ES logo.

Once you have the report, make sure your specific ICF is listed on the report (check concrete core width and manufacturing facility. If the form is listed, you’re set. If not, work with the form manufacturer to get the code officials the information they need. And then encourage your manufacturer to get the code certificates you need.

Doing so will ensure not only that future projects goes smoothly, but that the entire ICF industry moves ahead. Helping code officials and building inspectors understand and accept ICFs is critical to the long-term success of everyone in this industry. Not only will the industry gain more respect, and companies make more money, but as the Reward press release notes, “It’s just the right thing to do.”