By Vanessa Salvia

Photos courtesy of Rhino Form

Joey Hughes is a big thinker. He realized that he could build ICF homes faster and better by implementing panelization. Hughes rented a 7,500-square-foot warehouse in the Spokane Valley in Washington, where he’s able to produce enough panels for multiple houses a day for the general construction division of his company, Hybrid Home Builders.

And for Ben Baader of Rhino Form in Alberta, Western Canada, panelization is not a construction alternative, it’s become the norm. “Customers are wanting their panels connected prior to coming to the job site,” Baader says. “Our customers are expecting to have a crane on-site to lift and set the panels.” He’s been operating a panelization facility for the past 3 1/2 years.

Panelization basically means prefabbing an ICF wall. Instead of building onsite, what Hughes does is stack the blocks in the warehouse and put in all the window and door openings onsite. Baader’s forms are already manufactured as panels at the plant, and the customer can choose how many of these panelized forms they would like to connect with to build to any size. From there, those panels are loaded onto a trailer and taken to the job site, with the footing already established or a slab already in place.

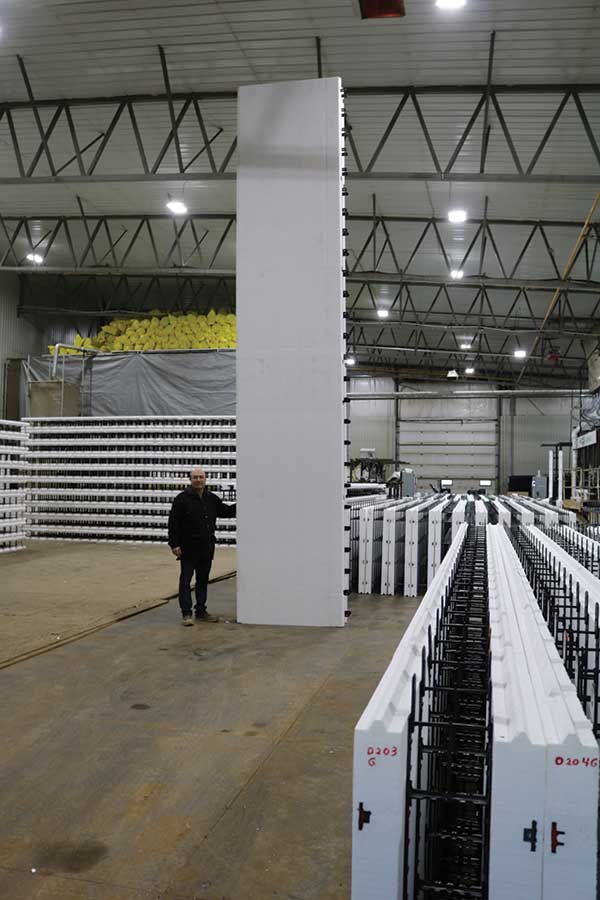

Baader says people now expect it because the homes or other structures can go up so much faster. “Some of our forms are up to 65 feet long and 24 feet tall all in one piece,” Baader says. “It’s great for oversize walls because traditionally you would have to set up scaffolding, for instance. With our system, you literally connect them together, lying on the ground or on the trailer, lift them up and put them into place.”

Hughes first had experience with panelization as a builder in Alaska about 15 years ago. While there Hughes experienced unforecasted 70- or 80-mile-an-hour or higher winds that would come through. “Sometimes you would go back to the jobsite and a windstorm would have blown up the site,” he says. “We would show up the next day and our wall sections would be laying on the ground, and then we’d have to pick up a bunch of damaged blocks and basically glue them back together and replace the damaged material. We found that panelizing ICFs enabled us to build faster.”

For one thing, they were able to eliminate weather-related issues. And by making the panels in an indoor warehouse environment, they were able to increase production as well. “Typically with ICF, we can build in a quarter to half the time of stick-framing a house, and the panelization enabled us to build even faster than that,” Hughes says. “Depending on the design of the building itself and whether it’s commercial or residential, we’re able to almost double our output capacity. We’re able to just unload the wall panels and stand them right up on the wall footing. With a minimal crew we can erect a complete house within a day.”

Hughes’s worksites are spread around Northern Idaho, Washington, and Montana, and prefabbing in the warehouse enabled him to basically be moving between multiple job sites more quickly. He can build panels for multiple jobsites and minimize travel in between sites. “That’s another thing that helps us increase our production rate,” he says.

That’s when he started prefabbing. For the past few years, Hughes has been building almost exclusively with Amvic blocks. He says it’s easy to train a crew on using the blocks, and the aligned interlocks on the blocks themselves help to reduce waste.

A 65-foot wide, 10-foot by 6-inch tall form being placed on a job in Stettler, Alberta. The weight on the scale includes the crane rigging.

“What we’re ultimately trying to do is use our labor as efficiently as possible,” Hughes says. “Whether it’s a pool, a house, or a commercial building, the more we can reduce our logistics such as through traveling time alone, the more we can increase our production rate.”

Baader is using Rhino Forms, the world’s first Full Height Insulated Concrete Form (FH-ICF). The panels are created for unlimited width, height, and angles. These panels go together differently than stacked blocks. The frame has two connecting sides, male and female, which are fastened with a cordless screwgun and lag bolt. Baader says he figured out panelization was much faster, so he began offering it to his customers, and they wanted it. “It takes a little more effort on our part to connect the panels prior to going to the job site, but it’s well worth it,” he says. “We’re putting a house together in less than a day.” Thanks to the panelization facility, Baader says Rhino form has seen 100% growth this year.

“No one’s turning down our panels,” Baader says. “We have a 100% sales success rate right now, and we’re selling them at

a premium.”