Fox Blocks Begins Manufacturing in Florida, Gets LA Code Approval

Fox Blocks, a division of Omaha-based Airlite Plastics Company, has announced its first satellite manufacturing location in Orlando, Fla.

Unlike most other ICF companies, Fox Blocks ships forms “factory-direct” to the end user, instead of through a distributor network. The company plans to partner with additional manufacturing facilities to help ease freight costs and shorten delivery times to customers throughout the U.S. and Canada.

On March 1, the company also announced that Fox Block ICF has been approved for building use in the City of Los Angeles, Calif. The research report, number RR25689 can be viewed on the “Technical Data” page of the Fox Blocks website, www.foxblocks.com.

The company has already received certification from ICC-ES, the State of Florida, and State of Wisconsin.

Dave Jackson, sales and marketing manager for the company, says, “This latest building code approval demonstrates Fox Blocks’ commitment to its customers in providing one of the most recognizable ICF wall systems among building code inspectors.”

California EPS Molder Expands ICF Production

APTCO, one of the largest custom molders of expanded polystyrene (EPS) on the West Coast, now produces ICFs.

One of a handful of molders in California, the company got its start molding insulated grape boxes for nearby vineyards. It now operates 24 hours a day, seven days a week, producing a wide variety of EPS products.

With 61 presses, a state-of-the-art bar coding system, and a large inventory storage capacity, the company is now looking to expand its ICF molding division

“We have molding capacity available for anyone looking at manufacturing ICFs on the west coast,” says Bob Shelker, sales manager for the company.

APTCO’s large warehouse can accommodate inventory for “Just in Time” shipments, and is strategically located in California’s Central Valley. “We can efficiently service the entire western region of the U.S., and parts of Canada and Mexico,” says Shelker.

The company, which has grown to be the biggest molder under one roof in North America, is also one of the most environmentally conscious. The small percentage of scrap produced is captured and compacted. The facility compacts an additional 350,000 lbs. of post-consumer EPS scrap as well, which is processed by a third party into weatherproof decking, roofing, and trim products.

Quad-Lock Training

Quad-Lock Building Systems has announced their 2008 training schedule, with more than 40 classes planned for more than 28 states and provinces.

Last year the company was one of the fastest growing ICF brands in North America, with growth in the double digits. The system consists of two independent panels which are assembled on-site with polypropylene ties. Because of the panelized design, Quad-Lock can accommodate congested rebar, unusual corners, and varying wall and foam thicknesses without the need for specialized forms.

All of this years training sessions will include Basic Installer Training, which focuses on hands-on learning. The course has been updated to include improved corner building techniques, an introduction to using foam decking for floors and roofs, and new take-away literature.

In six locations, an advanced installer training will also be offered, which covers—among other things—green roof and tilt-up applications for Quad-Deck.

Amvic Receives Award

Amvic Building System, an Ontario, Canada-based ICF manufacturer, has been recognized by the provincial government for their success.

In late February, the Honorable Harinder S. Takhar toured the Amvic facility in Toronto and presented the company with an “Award of Recognition” on behalf of the government. Takhar is minister of small business and entrepreneurship.

The award reads, “Entrepreneurship is vital to Ontario’s continued prosperity. Building a business requires, vision, hard work and dedication. I appreciate your commitment to excellence. Ontario applauds all your efforts that help keep our economy strong and vibrant.”

Amvic has experienced consistent, rapid growth since its founding in 1999. The company plans to continue this success by focusing on innovative green solutions for the building industry.

New Polyurethane ICF Unveiled

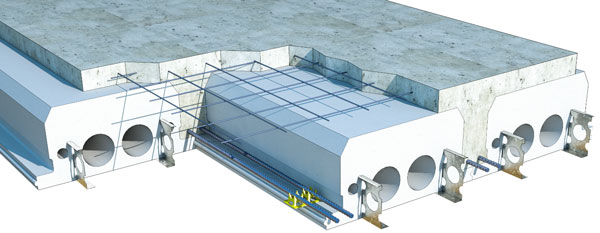

A new insulating concrete form, made from fiberglass and polyurethane, was unveiled at World of Concrete. Called EnergyForm, the product is significantly different from other stay-in-place forming systems.

The forms are large—eight feet long and 32 inches tall—which leads to faster installation, stiffer walls, and fewer joints and bracing. The polyurethane core is denser than the EPS typically used, which translates to a higher R-Value per inch of wall. The core is sandwiched between two fiberglass panels, which add strength and rigidity to the system. The polypropylene ties, located 12 inches on center, are marked with a divot in the exterior sheathing, and can create concrete core thicknesses of 4, 6, 8, 10, and 12 inches.

Designed by a contractor with 30 years experience working with concrete, the system claims to resolve blowout and bracing concerns, and can reach an 8’ ceiling height in just three courses.

NAHB Green Building Program Finalized

The National Association of Home Builders (NAHB) has officially launched their National Green Building Program.

“This is great news for our members and for all home builders, but more importantly it’s great news for home buyers,” said NAHB vice president and secretary Bob Jones, a home builder in Bloomfield Hills, Mich. Jones announced the program launch during a press conference at the International Builders’ Show in Orlando, Fla.

The program features an online scoring tool, available at www.nahbgreen.org, which shows the builder how to accrue points in seven categories: water, energy and resource efficiency; lot and site development; indoor environmental quality; global impact and homeowner education. The program sets point requirements in each category for the bronze, silver and gold levels.

Homes are inspected and verified by local green experts and the documentation is sent to the NAHB Research Center for review. If the project qualifies, the home can receive national certification from the Research Center.

“The time has come. Home buyers are ready for green, and NAHB is ready for today’s home buyers,” says Jones.

High-Performance Building Standard Open for Comment

A proposed standard that will essentially define high-performing buildings for building codes is one step closer to completion. Proposed Standard 189.1, Standard for the Design of High-Performance Green Buildings Except Low-Rise Residential Buildings, is now open for its second public review.

The new standard, spearheaded by ASHRAE, will outline minimum requirements for new high-performance commercial buildings and major renovation projects. It addresses energy efficiency, site sustainability, water use efficiency, materials and resources, and indoor environmental quality. The Illuminating Engineering Society of North America (IESNA) and the U.S. Green Building Council (USGBC) are also participants.

“This standard is an energy-saving stepping stone toward ASHRAE’s goal of net-zero-energy buildings,” says John Hogan, chair of the committee that wrote the standard. “It gives building owners or jurisdictions that voluntarily choose to adopt the standard a tool for constructing truly high-performing buildings that provide energy-efficient, safe and comfortable environments for occupants.”

To read the draft standard or to comment, visit www.ashrae.org/publicreviews. The public review began Feb. 22 and ends April 7, 2008.

IBS A Success Despite Low Attendance

Organizers of the 2008 International Builders’ Show (IBS) in Orlando, Fla., called the event a success despite a significant drop in attendance and exhibitors. The NAHB reported 92,000 attendees, although many exhibitors felt the actual figure was lower. It is an 11% drop from last year’s 103,000 show visitors.

The show, held Feb 12-15, marks the end of a four-year run at the Orange County Convention Center. Next year, the show will be held in Las Vegas, Jan. 20-23.

“The traffic is down, but the quality is good,” reported Jeffrey Feld at Jeld-Wen, a window and door manufacturer.

Many exhibitors in the Portland Cement Association (PCA) “Concrete Pavilion” had similar comments. “Instead of a company sending 4 or 5 people, the only person attending the show [this year] is the owner. And that person is here to evaluate products and make decisions,” noted one exhibitor.

The pavilion, organized by the PCA for the 20th year, covered a record 13,630 sq. ft. and included several major ICF manufacturers. Mike Collignon, residential program director for the PCA, was interviewed by the radio program, At Home with Gary Sullivan, where he discussed the benefits of concrete home construction, with an emphasis on insulating concrete forms. The show airs in more than 120 markets, including Cleveland, Nashville, Pittsburgh, San Francisco and Tampa. It also airs on XM satellite radio.

The PCA also sponsored an educational seminar, “Introduction to ICFs,” which was taught by Donn Thompson and attracted approximately 60 people.

New Prescriptive Standard For Concrete Homes

A new standard for concrete home construction, developed using an ANSI-accredited process, is now available.

Given the number PCA 100-07, the standard will eliminate the need for concrete homebuilders to hire an engineer on most projects, saving thousands of dollars. The long title is “Prescriptive Design of Exterior Concrete Walls for One- and Two-Family Dwellings.”

It specifically addresses stay-in-place forms, such as ICFs, and applies to detached one- and two-family dwellings and townhouses.

Steve Szoke, PCA’s director of code and standards, says, “Through a cooperative agreement between PCA and the American Iron and Steel Institute, we have expanded the scope to include prescriptive details for connections between concrete walls and floor and roof systems of cold formed steel framing. In addition, we have updated the connection details between wood framing and concrete walls,”

The designs are based on the requirements of ASCE 7-05, Minimum Design Loads for Buildings and Other Structures, ACI 318-05, Building Code Requirements for Structural Concrete, and tests results.

PCA Says Home Slump will Worsen

According to a recent PCA economic forecast, the grim conditions in the residential construction market are expected to worsen as the year wears on.

By the end of 2008, PCA expects a 9.5 to 10 month supply of homes to be in “inventory” for sale. These high home inventories will cause housing starts to decline an additional 25% from already depressed 2007 levels.

Home prices are expected to fall 8% nationwide. According to PCA economist Ed Sullivan, tight lending standards, weak economic conditions, and slower household formation will doom 2008 home sales.

“Even though buyers can get better priced homes in 2008, they must now have good credit scores and as much as a 20 percent down payment to qualify for loans.” he says “With job and income gains expected to slow during the next four quarters, most potential home buyers will back away from such a major purchase until the economy is more stable,” Sullivan said.