This magazine reviews submittals for recognition awards in various categories of ICF projects every year. Each year the project submissions are more outstanding, which makes it harder to get into the top three for voting, but it also makes the judges’ jobs more interesting. In any category, whether the project is selected as a winner, the architect/designer, developer, contractor, or owner has chosen to build with ICFs for the simple reason of what the product can do for them. In other words, because of the value proposition to them.

In the competitive sales and marketing of ICFs, there is a wide assortment of ICF benefits influencing why to use it. Only some of these benefits apply to every customer, builder, or designer. In the search to understand the value proposition of a building product, specifically for you or your market, how does one sift through all the material and listed benefits for each ICF to find the simple answer of what that product can do for you?

The starting point is to establish what is your main priority in selecting building products for a wall assembly. Naturally, the initial capital cost is a priority for everyone. Building materials costs and supply chains have fluctuated considerably in the last year, but both are settling down. For ICFs and concrete, initial capital costs are still highly competitive to high-performance wood framing or traditional commercial construction assemblies. The value-add for ICFs as the wall assembly is the reduction in on-site construction insurance, quick completion/occupancy timelines, and overall building operational cost savings. In addition, there is a definite positive return on investment (ROI) directly to the building owner or occupant based on future operating cost saving by having an ICF wall assembly.

As an architect/designer, the complexity of building science and the interface of multiple wall assembly building materials creates a risk factor. The goal is to specify and design a wall assembly, for either residential or commercial, that will function effectively and efficiently against intrusion from water, moisture, and air, for the life of the building. The other keywords are sustainability and resiliency. Research into ICFs manufacturers’ testing and reports satisfy all these requirements with a simple wall assembly to suit any project. Eliminating the risk factor in a building design is the value add. ICFs have a proven record of meeting all these requirements.

As a contractor, big or small, the main goal is labor and speed. All the other building science and energy efficiency benefits may not be of interest as long as the building is completed on time and within budget. Building with ICFs expedites the close-in, allowing the contractors to complete the building for occupancy faster, which expedites the financials for everyone. ICFs also eliminate deficiencies such as drywall pops, air leakage, and other wood frame-related issues. Other issues for contractors may be supply chain and available labor. ICF installation training is available, making it quick and easy to learn how to build walls correctly and efficiently. In addition, blocks are manufactured nationwide and have met past supply chain issues.

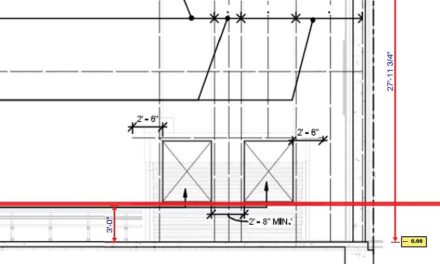

Developers typically build bigger projects, multiples of homes, or commercial projects. The key is always the budget and the timeline to completion. For the bidding process, the specifications to complete a traditional wall assembly may require six or seven building materials and application instructions for the interface of these materials. This could also involve three or four different contractors bidding to install these materials, plus an inspection to verify that the assembly meets the specifications. ICFs simplify this process as one basic product for a high-performance wall assembly, eliminating the interface of multiple products and multiple trades to build the wall.

If the developer or property manager owns the building, the value added will be the quick ROI. In addition, ICFs have proven cost savings — operational heating and cooling, maintenance, and insurance — plus appraisal real estate enhancements and less depreciation as a resilient structure.

For a homeowner planning to build their dream home, understanding all the building science benefits of ICFs may not be applicable. Instead, the key elements for value may be comfort and safety. A safe home that can withstand extreme weather events, like high winds and floods, offers security and peace of mind. Providing a comfortable and healthy indoor living space with thermal efficiency, healthy indoor air quality, and excellent sound attenuation are all value-adds provided by ICFs that should encourage homeowners.

As an ICF manufacturer, how should each of these potential clients view the relevance of the product? How can ICF solve a problem in design, construction, and sustainability? The main goal is in building trust in the product through the dealer supply chain, technical support, and customer service. Each potential client is looking for the specific value proposition in using ICF as it relates to them. Of the multiple benefits available for structure, building science, and constructability, pick one attribute that suits your specific needs. All the others become a bonus. The value-adds are always evident when the project is completed. Everyone involved typically says, “Why didn’t we use ICFs sooner? This has been a great project.”

The incredible designs and scope of this year’s award entries are a powerful sales tool highlighting design diversity and what is possible in building with ICFs. This is a credit to all the designers, developers and contractors who understand one or many value propositions offered by building with ICFs. As the construction industry evolves into more resilient and energy-conscious structures, experiencing the move to ICFs for all building types is proving to be an intelligent decision.

Tom Patton

Tom Patton had a 30-year architectural design background before joining the ICF industry in 2001 with the technical support department at ARXX. Over the last 20 years, Tom has worked with major ICF companies developing technical documentation, application details, and training programs, as well as consulting and promoting ICFs with various associations, including the ICFMA, NRMCA, and codes and standards committees. Currently, Tom is a Corporate Brand Ambassador for Fox Blocks and co-developer of the Fox Blocks Integrated Learning Center.