Education - 1st Runner Up

The town of West was a typical small Texas town. Located about 70 miles south of Dallas, it has a population of a few thousand and a sizable fertilizer plant, which had produced ammonium nitrate for farmers in the region without incident for more than 50 years.

All that changed in April 2013, when a fire at the factory—later determined to be deliberately set—triggered a massive explosion. Detonating with the force of 20,000 pounds of TNT, the blast destroyed much of the town and killed 15, including five volunteer first responders. The sound was heard more than 50 miles away, broke most of the windows in a seven mile radius, and left a crater 10 feet deep and more than 90 feet in diameter.West High School and West Middle School were immediately adjacent to the fertilizer plant, and the shockwave from the blast left both inoperable and structurally unsound.

When the immediate cleanup was completed, the town began to consider how to rebuild. Mike Kennaw, vice president of sales and marketing at Fox Blocks, says, “The community was absolutely devastated by this horrible disaster. The explosion destroyed hundreds of homes, businesses and three of the four schools in town. Construction of the new school was the centerpiece of the rebuilding effort, and symbolically provided the safe haven the community so badly needed.”

The school was designed with energy efficiency and structural superiority in mind. Not surprisingly, ICF was selected as the main structural wall component. Its blast, wind and fire resistance were major considerations. The exceptional acoustic performance of the ICF walls was also a factor.

Early in the planning stages, the concept of combining the high school and middle school into a single campus was explored, and ultimately selected. The 217,000-sq.-ft. design consists of two functionally-independent schools, connected by the cafeteria and gymnasium. Within the academic wings, collaboration space connects classrooms, allowing educators to remove the adjoining wall and expand the learning space.

Insurance payouts, FEMA, and the Texas Education Agency covered the $50 million price tag.

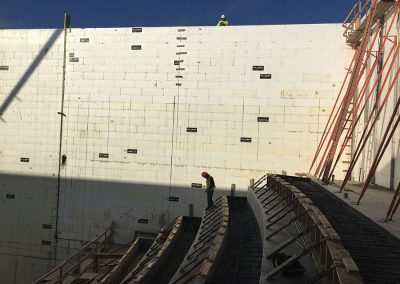

The grand architectural design and FEMA financial backing resulted in a very complex set of building plans. Steven Swoszowski, owner of Global ICF Innovations, Inc., was selected to do the ICF install. He reports, “There were about 50-plus corners throughout the building with wall heights ranging from 18 feet at the ‘low’ roofs to54 feet tall walls in the auditorium, with the average being about 30 or 35 feet.” Core sizes ranged from six to 10 inches, and there were hundreds of embeds. Swoszowski says, “The majority of the steel connections consisted of either shear connections (i.e. beam/joist to vertical weld plates) or bearing connections/beam pockets (i.e. beam/joist on horizontal weld plates).”

The 54-foot tall walls had no intermediate floors and required a group effort between Global ICF and Bartlett-Cocke, the general contractor, to ensure a safe and efficient wall stacking, pour and bracing system.

In addition to the scale of the project, the school was designed with a host of sustainable elements, such as steel-pan flooring from Vulcraft, solar shades and LED lighting. Kennaw reports the building meets LEED standards.

As the community’s youth were meeting in portable classrooms until the new school was finished, the contractors were under pressure to keep to an ambitious schedule. Swoszowski claims that he sometimes poured 18 vertical feet of wall in a single day.

The 123,000 sq. ft. of ICF (including 20,000 sq. ft. of interior walls) were installed in about 180 working days spread over the better part of a year. Swoszowski says, “This project—like many others in this region—experienced excessive amounts of adverse weather delays. The winter months brought rain and surprising cold which posed challenges to the critical path of the project.” The unpredictable schedule created difficulties in maintaining adequate manpower at the isolated jobsite.

The project was, however, able to meet schedule, opening in August 2016 in time for the school year.

Just as the blast received significant international news coverage, the new ICF school was a focus of national and regional media attention as well. The school was featured in the major media outlets in Dallas, and was the focus of an hour-long TV documentary broadcast on the state’s PBS affiliate. ENR magazine recently named it “2017 Best Project” for the Texas and Louisiana region.

Swoszowski says, “We were very proud as ICF installers to be a part of this project and help deliver a new school that will stand strong for the community and represent the rebuilding of a town after such a terrible disaster.”

Kennaw says, “The new West Middle School/High School project is one of the cornerstones for the ICF industry in the South Texas region. It has ushered in a new way of thinking for school boards, design professionals and contractors. It met the school board’s evolving needs while allowing for flexibility and sustainability. While the explosion left the city in need, watching the community and other organizations help rebuild the city has been inspirational and a true example of the American way.”

Project Statistics

Location: West, Texas

Type: High School/Middle School

Size: 217,000 sq. ft. (floor)

ICF Use: 123,000 sq. ft.

Cost: $45 million

Total Construction: 72 weeks

ICF Installation time: 180 days

Construction Team

Owner: West ISD

General Contractor: Bartlett Cocke

ICF Installer: Global ICF Innovations, Inc.

Form Distributor: Fox Blocks

Architect + Engineer: Huckabee Architects

ICF System: Fox Blocks

Fast Facts

Extensive national publicity

Wall heights topped 50′

50+ corners

Single-day pours of 18′