2011 Heavy Commercial

1st Runner-Up

The Phoenix Archdiocese has become a major influence in the ICF industry; they’ve built no fewer than 10 major ICF projects in the area, with at least eight more on the drawing board.

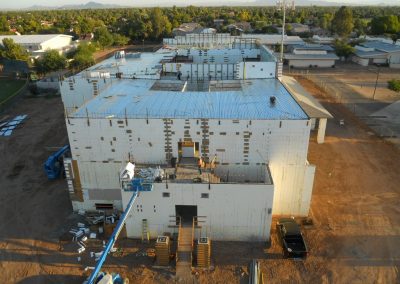

Seton Catholic High School is one of the most ambitious to date. Rod Fetters of ICF Specialist, LLC, did the formwork. “This was an extremely intricate build,” he says. “In addition to all the exterior walls, 80% of the interior walls were ICF as well, on all three levels. This created an intense network of T-walls and other intersecting elements. Wall heights were 15 feet per floor.”

The tight construction schedule and immense volume of concrete required—nearly 4,000 yards—meant that pour days usually required two pumpers working simultaneously.

Fetters faced tight deadlines, as Redden Construction, the general contractor, had committed to an ambitious schedule. In the end, the crew from ICF Specialist erected 117,000 sq. ft of ICF walls in 135 days. Thomas Johns, the project manager for Redden Construction, turned the building over to its new owners 412 days after breaking ground.

Fetters reports, “The rigorous timelines for the completed project were maintained using two pump trucks at a time. The Giraffe Tall-Wall Bracing system allowed us to pour 15-foot lifts.” He also credits Hambro floors joists, which were used to support the concrete floors and ceiling. “We could pour the floors with no additional supports or shoring, which allowed for instant access of other trades as soon as they were placed.”

Seton Catholic pioneered several new products as well. It was the first large-scale use of BuildBlock’s knockdown form, BuildLock. Fetters says, “These forms were instrumental in construction of deep basement walls and heavy vertical rebar schedule. They stood up to the extreme head pressures we sometimes generated with zero blowouts.

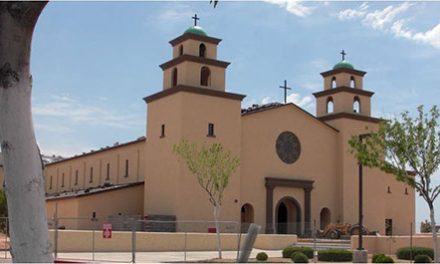

Seton Catholic High School is truly a milestone ICF project. The ICF rooftop arches and parapets, radius walls and arched entryways, and the maze of interior walls all stand straight, level and plumb. It set new standards for sustainability—it would likely be certified LEED-Gold—and proved the suitability of several new products. It’s no wonder that Fetter says, “this project will go a long way to inspiring other churches and businesses in the Southwest to use ICF technology.”

2011_Project_Profile_Seton_High_School_007

The tight construction schedule and immense volume of concrete required—nearly 4,000 yards—meant that pour days usually required two pumpers working simultaneously.

Project Statistics

Location: Chandler, Ariz.

Type: Educational

Size: 60,200 sq. ft. (floor)

ICF Use: 76,115 sq. ft. (all exterior walls) plus 40,500 sq. ft. of interior ICF walls and 2,000 sq. ft. landscaping

Cost: $6.8 Million

Total Construction: 412 days

ICF Start-to-Finish Time: 135 days

Construction Team

Owner: Phoenix Catholic Archdiocese

General Contractor: Redden Construction

ICF Installer: ICF Specialist, LLC

ICF Distributor: BuildBlock Direct

Architect: HDA Architects

Engineer: PK Associates

ICF System: BuildBlock

Fast Facts

Owner has built 11 large-scale ICF structures, with nine more on the drawing board.

Tight construction timeline to meet school calendar

80% of interior walls are ICF, creating intense network of T-intersections

Three stories (one underground), all have 15-foot ceilings

28” square columns of ICF support heavy roof loads

Rooftop arches and parapets formed with ICF

Used fiber admixture to eliminate all horizontal rebar (except lintels)

Hambro floors allowed instant access by trades beneath new concrete floors

Featured in local newspapers and church magazines

Like what you read?

Yearly Subscriptions Starting @ $30

0 Comments