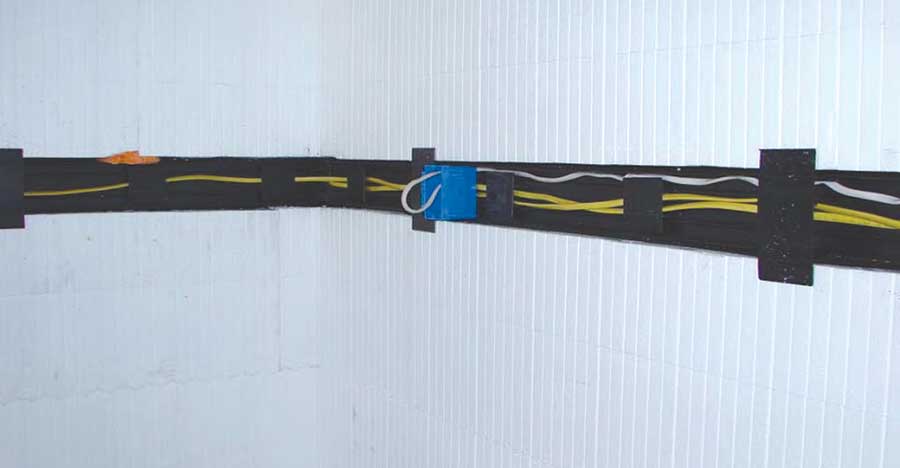

Virtually any amount of wire could be installed -or retrofit- in the roomy chases made by Solcraft.

Many contractors not familiar with ICF construction may believe that it’s more difficult than traditional stick-frame building. In truth, it’s actually easier to work with ICFs than many conventional systems.

And that’s true for subcontractors, too. From hanging drywall to installing utilities, many subcontractor tasks are made simpler with ICF construction. Let’s look at just one example: Installing electrical wire, telephone jacks, or audio-video cable after the drywall is installed.

While the procedure is fairly straightforward and simple, it is really only suited for change orders and retrofits. And some of the techniques discussed here may need to be adapted to meet local building codes.

Super-Groover Method

The easiest and most elegant installation method requires using a high-power hotknife from Wind-Lock called the Super-Groover. It’s available with a variety of cutting wires, including a “conduit blade” shaped like a keyhole which is the, ahem… key to making this work. (If you do not own a hot knife, the local ICF distributor may have one available for rent.)

The first step is to mark the location of the missing junction box, trace around it, and remove the drywall. A zip tool works best, but a keyhole saw will also work.

Next, remove the foam so that the junction box sits flush with the drywall. There are several ways to do this; the cleanest and easiest is to use the EBX or “electrical box” blade that comes with the Super-Groover. An optional six-inch sled will ensure that the cut is perpendicular to the sheetrock. If these attachments aren’t available, other foam removal methods will work.

Now, layout the route between the new junction box and the box the power will be coming from. Straight lines will make pulling the wire easier, but plan carefully; the hot knife cannot cut through plastic (or steel) ties. Most brands of ICFs have a small gap between furring strips at every horizontal joint. Panel systems like Quad-Lock and Smartblock are more flexible and can be cut anywhere except the joint.

Once the route is laid out, cut along the line with a circular saw. The blade should be set just deep enough to completely penetrate the drywall.

Attach the conduit cutter to the Super-Groover. Start at the new junction box opening, and run the Super-Groover along the saw cut. The hotknife blade will slide easily along the 1/8” saw groove while melting a circular wire path in the foam behind the drywall.

Once the channel has been melted out, it’s simple to pull the wire through to the new box. The 1/8-inch saw cut is easily filled with standard joint compound.

No Hotknife Method

If you cannot obtain a Super-Groover, and you need to retrofit a utility box into an ICF wall, it can still be done fairly easily. Unlike frame construction, where drywall joints have to align perfectly with the wall studs, on an ICF wall, the joint can be placed wherever it’s convenient because the drywall is continuously supported.

This installation method is fairly similar to the steps listed above. Mark the location of the junction box, and remove the drywall and foam.

Next, layout and mark the wire route between the junction boxes. Keep in mind that if the wire chase will be made with an electric chainsaw or router, the layout can cross plastic ties (but not steel ones). Also mark a line two inches on each side of the route line.

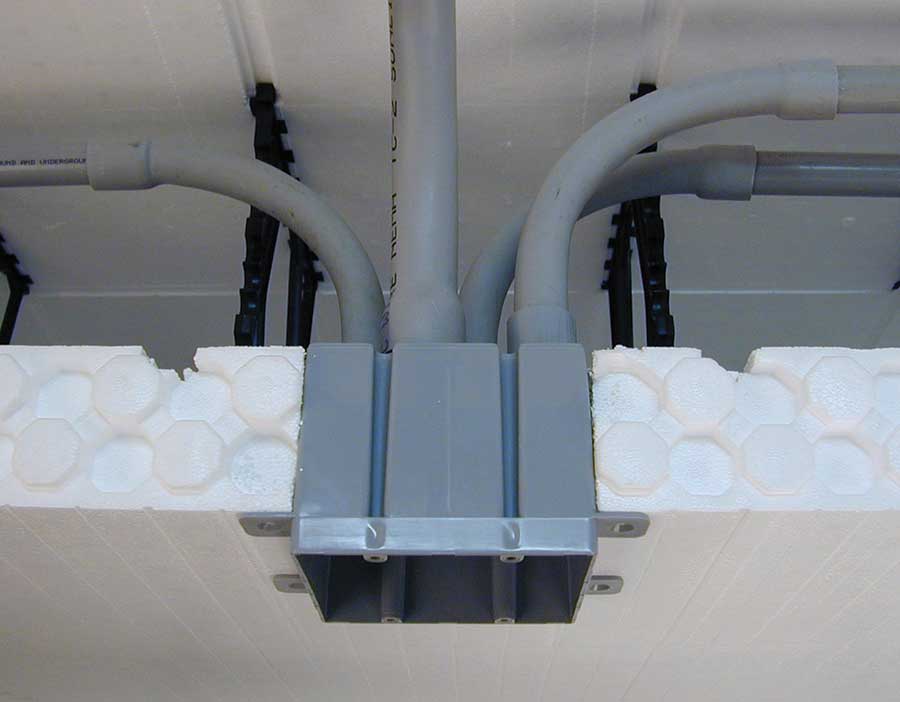

Conduit placed in the wall core during construction allow easy retrofits for the life of the building without destroying the insulation.

Using a circular saw or jigsaw, cut along the two outside lines just marked. Remove and carefully set aside the 4-inch strip of drywall. Then, using your preferred foam removal method (router, chainsaw, barbecue grill lighter, craft hot knife, etc.) cut a chase for the wire. Once the wire is installed, the strip of drywall can be easily screwed back into place. The pair of 1/8” saw cuts are filled with joint compound.

Pre-Installed Chases

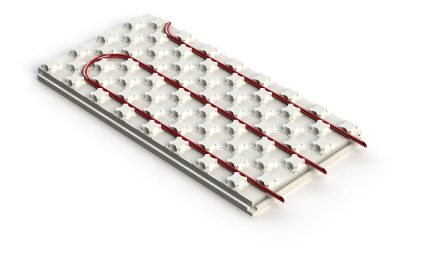

Perhaps the easiest way to install wire after the drywall is in place is to build the home with conduit in place. This can be done in three ways:

The first is to install traditional steel or plastic conduit in chases cut in the foam. If additional wires need to be pulled, any electrician can easily do so.

PlastiLock offers custom-made junction boxes and conduits for installing wires in the concrete core of the wall (see Installing Utilities in the Oct.’05 issue of this magazine). Inventor Brad Hebig says that not only does this make the building more adaptable, but it also creates an additional profit center for the ICF installer, more since the electrician only has to pull wires.

The third option is the new E-Connect system marketed by Solcraft PDC. It is installed in the foam prior to the concrete pour and provides a chase three inches high and 2 ½ inches deep. For the life of the building—predicted to be several hundred years—upgrades can easily be made.

Precautions

Regardless of how the wires are installed, be sure to follow local building codes. Three items are of particular importance. First, any electrical work in a house (other than your own) needs to be performed by a licensed electrician. Second, all electrical work will likely need to be inspected by the local building official. Third, and most importantly, all wires need to be at least 1.25” away from the face of the drywall. The 2006 International Residential Code (IRC 2006) specifies, “If this distance cannot be maintained, the cable shall be protected by a steel plate or sleeve at least 1/16” thick.” In commercial work, the cables must be sleeved in all cases.

Conclusion

ICF use is becoming increasingly common as builders and subcontractors learn just how easy it is to work with insulated concrete forms. Being able to install wiring after the drywall is in place, usually as a remodel or retrofit application, is just another example of the ease of ICF use.