ICFs are known to save on heating and cooling costs. But in order to fully realize this benefit, the mechanical systems—heating, cooling and ventilation—must be properly sized. Additionally, non-traditional systems such as in-floor hydronic heat, geothermal HVAC, and mini A/C units are often more efficient than common methods such as forced air.

Design Guidelines

Some HVAC contractors are unfamiliar with the superior performance of ICFs and end up installing oversized equipment that not only carry a higher price tag, but also cost more to operate. An oversized HVAC system will cost more to purchase and will consume more energy every time it switches on. Additionally, oversized systems will lead to larger temperature swings and reduced comfort.

The solution is to ensure the HVAC system is specified by someone familiar with ICFs and calculates system requirements using software such as the HUD/PCA “HVAC Sizing for Concrete Homes” rather than rules of thumb or outdated tables in an ASHRAE manual.

Heating and cooling systems using a combination of components from different manufacturers are rarely as efficient as those using equipment from a single company.

Variable-speed systems also deliver better energy performance than single-speed equipment. These systems will typically run longer but at lower speeds, which provides better humidity control and reduced operating costs.

Radiant In-Floor Heat

Radiant floor heating offers many advantages over traditional heating systems. It is energy efficient, quiet, and draft-free. With in-floor heat, even in tall rooms, the warmest air is near the ground. The most important advantage is the improved comfort level, especially when combined with a concrete floor. Because in-floor heat systems are warmest near the ground, they distribute heat in a way that mirrors occupant’s optimum thermal comfort.

Hydronic Heat: This is the most common in-floor system, which uses a heated liquid—typically water or a water-and-glycol solution—circulated through a layout of polyethylene (PEX) tubing of various diameters under the floor to deliver the required number of BTUs to the occupied space.

Tubing runs are generally limited to 300 ft., so most homes and commercial buildings will have multiple runs, each controlled by a separate thermostat. Zoning allows areas of the structure to be heated to different temperatures based on space utilization and occupancy rates of the space.

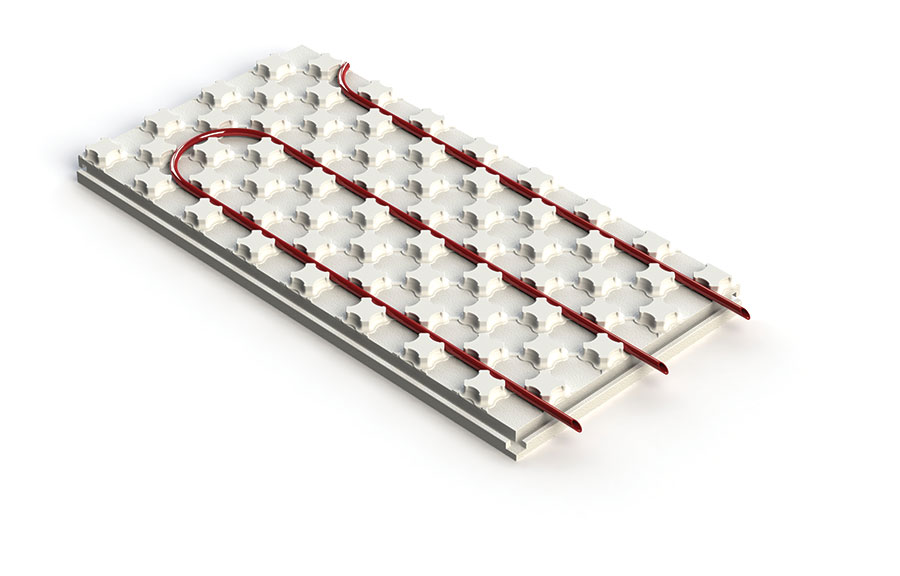

Until recently, tubing was attached with either a commercial grade stapler (for wood floors) or using wire ties to attach the tubing to the mesh. Today, though, foam underslab panels are available that provide insulation, a vapor barrier, and tubing attachments in a single sheet. The installer simply walks the tubing down into the nibs without the need for any specialty tools. These products save tremendously on labor costs.

Creatherm made one of the first “walk-it-in” radiant floor panels, and they’re still a popular choice. Heat Sheet, made by the same consortium of EPS molders that produce Logix ICF, is another option. A third choice is the Amvic Insulated Radiant PEX panel.

Ampex is molded with a graphite-enhanced EPS bead for additional efficiency. Like the other panels, The PEX tubing is easily installed by walking on the tube, and the panel nubs form a “mushroom” shape under pressure to lock the PEX piping firmly in place. Ampex Commercial uses a higher-density foam and is one of the very few insulated radiant PEX panels on the market to accept up to one-inch diameter piping.

All three products measure 2’x4’ with grooved interlocking edges for easy layout installation. They’re available in a variety of thicknesses, and the nib pattern repeats itself every few inches to easily accommodate any tube layout.

Pneumatic Heat: Legalett offers a different sort of heating. The system uses in-floor hot air instead of water. Ken Williams says, “The end cost is about the same or slightly cheaper but the major difference is that there’s no water running though the floor that could be damaged during the construction phase.”

The system originates in Scandinavia, and Williams says that about 95% of homes in Sweden are heated using this system. Legalett uses a foam underslab layer that is integral to the building’s foundation, which can have advantages. “There’s no need for deep footings or frost walls,” he says. It distributes the weight of the building across the entire slab, meaning soils need only 450 lbs. per sq. ft. bearing capacity as opposed to 2000 lbs./sq. ft. required for traditional footings.

The foam is topped with six or eight inches of concrete. “Once it comes up to temperature, it’s easy to maintain,” says Williams. “Often, solar gain from the daytime is enough to heat the slab and retain heat during the evening and nighttime hours.”

With Legalett, the air is heated with electric coils, or indirectly with hot water. Hydronic systems typically use electric, gas, or fuel-oil-fired boilers, although wood burning stoves, geothermal, solar and waste heat units are also available for hydronic radiant heat applications.

Geothermal Heat Pumps

The efficiency of in-floor heat can be dramatically improved by coupling them to ground-source heat pumps (GSHP). These exchange heat with the earth, effectively pre-heating (or pre-cooling) air virtually for free, as the earth remains at a relatively constant temperature year round. Several types of systems have evolved, including “open loop” systems that use fluid in a reservoir (such as a pond, well, or lake) as the heat transfer fluid. “Closed loop” systems can be installed vertically in wells or horizontally in trenches. Some use coiled pipe to increase the heat transfer per foot of trench.

For those interested in a comprehensive discussion of the subject, a 40-page report, sponsored by the U.S. Department of Energy (DOE) was prepared in 2008 by the Oak Ridge National Laboratory and is available online at www.geoexchange.org.

GSHPs have proven themselves in residential and commercial applications across the continent. The first net-zero school in the world, the all-ICF Richardsville Elementary in Kentucky, used geothermal heat pumps in conjunction with the HVAC and water heating systems.

Cooling

As noted above, GSHPs can be used for cooling as well as heating. The earth’s constant 50-degree temperature (Fahrenheit) is more than sufficient to keep a building cool. However, it’s not the only way to efficiently cool an ICF building.

One method that is rapidly gaining popularity is the use of ductless mini-split A/C units. Instead of installing a single central air conditioning unit that uses forced air ductwork, these work like those found in motels and apartment complexes across the country. The cost of these mini A/C units has come down considerably in the last decade, and by installing a series of wall-mounted units, it eliminates the cost of ductwork and gives occupants the ability to adjust the temperature in just one part of the building.

Finally, innovative cooling technologies previously only seen in commercial construction are getting smaller, more cost effective, and are starting to make inroads in the residential market. These include chillers, evaporative coolers, and hybrid systems.