Having now been involved with ICF construction for more than 18 years, and in that time having produced more than 170 ICF structural solutions, it’s been interesting to see how ICF construction is currently being considered for more and more applications. While most people might think that ICF should be used for primary residential or commercial projects, it’s far more versatile than that. The following is a list of possible applications:

- Primary residential

- Primary commercial

- Partial residential remodels

- Partial commercial remodels

- Schools

- Churches

- Warehouses

- Workshops

- Basements, both residential and commercial

- Safe rooms

- Swimming pools

- Foundation walls

- Multifamily projects including multistory and mixed-use

- Retaining walls

- Mono pour footings

and walls - Pump houses, both private and municipal

- Accessory dwelling units (ADUs)

- Other small stand-alone buildings, like backyard art or yoga studios

There are no doubt more applications than above, but the reader should now be getting the general idea that ICF is a versatile building method.

The Building Advantages

There are basic differences between wood frame/masonry construction and ICF construction, some obvious, but some not so obvious. The following is a review of some of those differences.

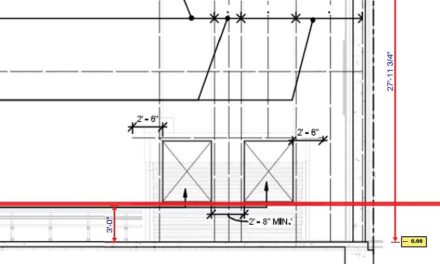

A 6-inch concrete core is approximately 10 times stronger than wood shearing, and that is extremely significant. This allows more adventurous architectural design, affording the flexibility of more and/or larger openings, and also placing openings where wood framing would make that very difficult.

Over the past three years, wood products, whether it be dimensional lumber or engineered wood products, have escalated in price almost exponentially, and to a large extent have now stabilized at a lower level, but around 20% higher than where they were originally. In the same period, ICF foam products have increased around 10 to 15% only, and concrete costs have risen by the same order. Rebar prices have escalated more, but fortunately, these represent a small percentage of the overall ICF installation.

The elimination of thermal bridging is a major factor in the true performance R-value of an ICF wall. However, the thermal mass of the concrete contributes significantly to the ICF wall performance, frequently achieving a performance R-value upwards of R-40! This fact was used very effectively by one of our clients in Iowa. This contractor produced a municipal pumping station that did not require ancillary heat, even in a severe winter. The heat generated by the pumping equipment, combined with the exceptional R-value of the building envelope, were sufficient to keep everything above freezing temperatures within the pump house. So not only did ICF construction save initial equipment and installation MEPS costs, the reduced operating costs were significant.

Naturally, this superior thermal performance leads to huge energy savings for all structures. It is not uncommon for property owners to achieve 60% energy savings in an ICF house, compared to those achieved in a code-compliant wood-frame house. An illustration of this can be summed up by a comment made by a client who recently moved into his newly constructed ICF house, in Grants Pass, Oregon. He said, “Checked the outside temp today in the late afternoon, 104 degrees, but inside it was only 76 degrees. We have no air conditioning running; it’s all ICF and opening the windows at night and closing them in the morning. Great stuff!”

A significant benefit of ICF construction is the quietness of the enclosed interior space. Noise from wind, traffic, rain, air traffic, and even neighbors, is virtually eliminated. Over the past several years, my engineering firm has undertaken two ICF midrise mixed-use building projects, for the same Maryland client. In each case, there were four stories, with retail/offices on the ground floor, and three stories of multifamily units above. All interior demising walls and corridor walls are ICF, as is the exterior building envelope. Our client has had feedback from his residential tenants that they hear no noise from adjacent tenants, and that their utility bills are the lowest they’ve ever experienced!

Speed of Construction

There is no doubt that ICF construction is faster than most other construction methods, including tilt-up. As an example, a contractor placing ICF for the first time on a project in Cave Junction, Oregon, was able to place a 2,700-square-foot, single-story footprint, in just 11 days from start to pour. This included installing all the required wall bracing, bucking and bracing all the window and door openings, and all the other prep work necessary to get to the pour point. And this was with a four-man crew. He was very pleased with the simplicity of the installation, and is now a confirmed ICF convert!

Added Security

We have seen over and over again in recent years where whole communities have been ravaged and destroyed by fire. Santa Rosa in California, Paradise in California, and more recently, Phoenix and Talent in Oregon are just a few. While nothing can be called absolutely fireproof, without doubt, ICF construction is non-combustible. When experiencing a total loss occasioned by fire, the property owner is devastated by not just the loss of the structure, but probably more so by the irreplaceable loss of the contents. In the case of a residence, the family pictures and videos, maybe a special memento that was placed proudly for all to see, the contents of a cedar chest, family jewelry — the list goes on. At the very least, when an ICF structure is confronted with a fire, it has a much greater chance of withstanding that fire and protecting those precious contents.

Fire may not be the environmental hazard alone. Maybe it’s earthquakes, or tornadoes, or hurricanes. Again, due to the incredible strength of an ICF structure, it rarely succumbs to these natural disasters and again protects both the contents and the inhabitants.

And quite literally, ICF construction is bulletproof! Six inches of reinforced concrete affords virtually unequaled protection from gunfire attack. While that may not be important to many, there are some locations and applications where this is of paramount importance, and provides a very cost effective solution to that localized problem.

Better Living & Working Environments

The peace of mind living within an ICF structure has itself a cost-saving element. Minimal maintenance, reduced stress, reduced utility bills — all these factors lead to a calmer viewpoint for the property owner. With building loan interest rates currently rising, many property owners are now considering ICF construction in lieu of other forms of construction. Many lenders reflect the building method within the rates offered.

Conclusion

The net result of all the above is that in both the short term and the long term, ICF construction saves the property owner money. Money can be saved in the primary building cost. But in addition, the operating cost of an ICF structure is also substantially less, leading to very long-term cost savings. Taking all the above into consideration, it’s little wonder that ICF construction is finally being seriously considered for a wide range of new building projects.

Dave Gowers

In the 51 years since graduating from London University in the United Kingdom, Dave Gowers has acquired extensive experience in concrete construction through diverse commercial, residential, and industrial projects in several countries. Dave resides in Southern Oregon with his wife and business partner, Jennifer. Dave holds a PE license in 14 states/territories and is the principal of Dave Gowers Engineering LLC, and co-principal of Cascade ICF LLC. He can be reached at 541-660-9661 or dave@dgengineering.com.