Light Commercial — Winner

The Coca-Cola Pavilion is 18,000 sq. ft. of mixed retail and restaurant space at The Walt Disney World Resort near Orlando. Designed to appear as a remodeled vintage industrial space, it is one of the first ICF applications in a theme park.

It was also an extremely demanding and highly visible installation, as the project was seen by the thousands of visitors entering the park every day.

The complex project utilized cast-in-place removable forms, CMU, regular masonry veneer, structural steel, glass, and a number of other systems.

Turning Leaf Construction served as the ICF installer for the project. They had previously built a smaller ICF project for Walt Disney World, so when this job came up for bid, they were a natural choice. Fox Blocks was the basis of design, and was ultimately selected for the build.

The general contractor, DPR Construction, had never built with ICFs before, so the two participated in a series of pre-construction meetings discussing how ICFs integrated with other structural and design components. It also allowed the two companies to forge a relationship that proved beneficial when challenges arose later.

“If you’ve ever been to a theme park, there’s just not a lot of extra space, and that was certainly the case here” says John Riddle, an executive at Turning Leaf. Hedged in by other projects, they had only 15-20 feet around the perimeter of the project for both construction and material staging. Deliveries were restricted to a single entrance, and that was only available during the overnight hours. “The ability to easily offload from the delivery truck, and that the bundles were lightweight was a labor and time saver,” he says. The ability to brace the forms from the interior side of the walls was critical. In fact, the concrete block crew that built one wall of the building had to negotiate additional space in order to erect their bulky scaffolding on the exterior.

The project used a wide range of materials, and required coordinating structural steel, cast-in-place removable forms, CMU, regular masonry veneer, glass, and a number of other systems.

As the ICF crew proved their abilities, their scope of work expanded to include a massive cast-in-place beam and cantilevered slab. The beam spanned nearly 36 linear feet and was nearly six feet tall. The cantilevered slab was six inches thick, spanned the entire length of the beam and cantilevered more than four feet outside the ground floor walls.

The biggest challenge for Turning Leaf was when they learned, after winning the bid, that all concrete pours had to take place between 2:00 and 7:00 am. Riddle says, “This constraint was not included in the work scope during the bid, and the GC did not allow for any change orders to accommodate this requirement.” Obviously this required new negotiations with the ready-mix plant and pumpers. “After the first pour, we were able to adjust our planning and better assign work hours for our pour crew and negotiate better rates with our ready-mix provider for after-hour plant openings,” he reports. “Our installation team became extremely efficient.”

In total, they placed 8,000 sq. ft. of ICF in 39 days, estimated to be 18-20 days faster than CMU.

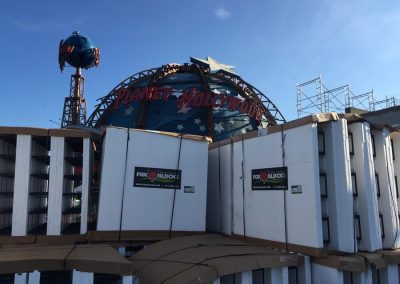

Finished in July of 2016, the building is now a focal point of Disney’s reimaging of the area. Immense “Coke Glass” panels were layered on the full height of north and west faces of the building. They hang from cables secured to the ICF walls. Vintage brick was used on the other two elevations.

Riddle says, “The location, combined with the namesake sponsor, create constant attention to the structure. The construction was in constant view of the public and under daily observation of the Walt Disney Imagineering team. Certainly, there aren’t many other ICF projects that have the consistent level of traffic this building sees. This is incredibly significant to ICF projects being used in any other theme park, commercial, and multi-family structures throughout the U.S.”

Project Statistics

Location: Lake Buena Vista, Fla.

Type: Theme Park Retail/Restaurant

Size: 18,000 sq. ft. (floor)

ICF Use: 8,000 sq. ft.

Total Construction: 40 weeks

ICF Installation time: 39 days

Construction Team

General Contractor: DPR Construction

ICF Installer + Form Distributor: Turning Leaf Construction

Architect: Baker Barrios Architects, Inc.

Engineer: Amore Engineering, Inc.

ICF System: Fox Blocks

Fast Facts

Extremely limited footprint

Mandated “graveyard shift” pours

GC was first-time ICF installer

Multiple systems to coordinate