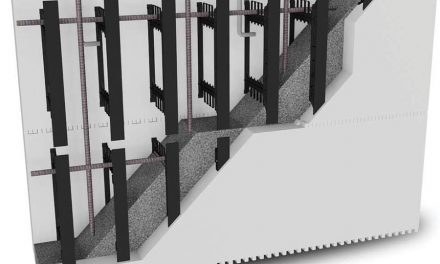

Structural Insulated Panels (SIPs) are sort of like cousins to Insulating Concrete Forms (ICFs), especially in the residential construction realm.

They’re just similar enough – strong material sandwiched around high-tech insulation – that they can compete for the honor of forming a home’s walls. But as cousins get older, they often stop fighting for family pre-eminence and form a connection.

Many in the ICF and SIP industries are starting to recognize that their products comprise an excellent combination for structural strength and energy-efficiency. ICF walls combined with SIP roofs can form a nearly impenetrable fortress for air that may have any bright ideas about trying to escape from a house.

That’s why leaders in both industries, rather than working against each other for market share, are working together to answer the burning question of how best to connect an ICF wall with a SIP roof.

“We really don’t see ICFs and SIPs as competitors right now,” said Chris Schwind, public relations manager for the Structural Insulated Panel Association. “I think the main competitor to SIPs is conventional stick framing.”

Schwind believes the day when ICFs and SIPs compete for a share of a major market segment is a ways off.

“In the future, if we have people choosing between an ICF wall and a SIP wall, we’ll have reached the point where people will have become cognizant of the energy-efficiency,” Schwind said. “Right now we’re not at that point.”

At their most basic, SIPs are high-performance panels made by sandwiching a core of rigid foam plastic insulation between structural skins of various types, the most common of which is oriented strand board. Because they are factory-made, they can be custom-designed to the needs of each home.

And while SIP manufacturers would love to see every house built with SIP walls as well as SIP roofs, they’re not going to buck the growing consensus that ICF walls and SIP roofs are a great combination.

“My job is to sell SIPs wherever I can,” said Butch Johnson, marketing manager for Grenada, Mississippi-based General Panel, one of the nation’s leading manufacturers of SIPs. “But if I had my choice, I’d combine ICF walls with SIP roofs.”

And Johnson has his choice in the sense that General Panel is a partner with ICF manufacturer LOGIX – a connection that has General Panel seeking a way to sell the two as a combined product.

“In looking at the ways you can build, we’re of the opinion that the best way to build is with an ICF wall and a SIP roof,” Johnson said. “It gives you better numbers across the board with heat and insulation with an ICF wall than a SIP – and there’s a huge difference with high winds.”

Those in the business of selling SIP walls also recognize another reality: ICFs are well ahead of them in terms of mainstream recognition and acceptance. While most traditional stick builders still have a long ways to go in learning the art of installing ICFs, the number of builders who have taken the plunge is growing all the time.

“For the most part, ICF walls are going on right these days,” Johnson said. “I think it’s probably hit mainstream more. When we discuss these things in our corporate sales meetings, one of the things we look at is product lifestyle, and clearly, ICFs made the mainstream faster than SIPs.”

After his previous home was destroyed in a hurricane, Fred Bales rebuilt using the strongest materials possible. Built on a site overlooking the Rappahannock River in Virginia, the home combines the strength and energy efficiency of ICF walls with a SIP roof, completing the “energy envelope.”

But while SIP manufacturers are more than happy to share a house with their ICF cousins, builders combining the two materials are grappling with a crucial challenge – that of properly connecting ICF walls to SIP roofs, particularly if the idea is to optimize energy efficiency.

The issue is challenging enough that some heavy hitters are conducting a full-fledged research project to determine the answer. They include the U.S. Department of Housing and Urban Development, the National Association of Home Builders and the Portland Cement Association – all of whom have a stake in the outcome.

“It’s really too early to tell what the final recommendations will be,” said Donn Thompson, resident technology manager for PCA. “They are focusing on the connection at the top of the concrete wall and the SIP panel itself – how best to do that. The beauty of the research is the group that’s has been working with the NAHB center that’s actually conducting the research. It represents our industry and the various SIP manufacturers, as well as some structural engineers and architects, so I think we’re going to get some good practical findings.”

Why so much interest in this question on the part of so many high-level groups?

“We’ve identified that SIP systems combined with concrete wall systems are really the most effective use of SIPs,” Thompson said. “They make for a very efficient combination with various concrete wall systems. What was lacking in residential construction was a consistent standard that would identify the best approach to attaching SIP roof panels to different kinds of concrete wall systems.”

Of course, even attaching a conventional roof to an ICF wall takes some getting used to. Traditional stick builders who have always used mechanical connections to attach roofs have to get used to the idea of bolts and straps. Engineers who have always worked with wood can be taken aback by the weight of the ICF wall.

But ultimately, it’s about holding everything down.

The NAHB research may uncover a revolutionary new strategy, but the basic concept for builders at this point is to run roof beams exposed under the panels for the hips, valleys and ridges, then tie the roof to the walls using strap-tie hold-downs embedded into the concrete and wrapped around a tapered mudsill anchor.

“It always comes down to firmly securing a top plate and then doing whatever you have to in order to get that top plate plum square level,” Johnson said. “The detail we use is generally a bolt at the top of the wall, tying on the top plate, and that being the fastening point.”

Builders with experience attaching SIP roofs to ICF walls say the job gets harder as the roof design gets more complex. The more hips, valleys and ridges – the harder the job.

“The hips and valleys with the SIP panels have to be thought out,” said Peter Coughlin, president of Oregon-based Peter Built Homes, who has built about a dozen homes that combined ICF walls and SIP roofs. “The one doing the panel drawing needs to have his head glued on, and he needs experience in the field to make a drawing correct.”

Johnson agreed that the design of the roof usually determines how difficult installation will be.

“If the roof has a lot of elevation changes – hips and valleys – it’s awfully difficult to work a SIP roof out,” Johnson said. “So the overall design of the roof and of the house is what decides if it will be a complicated roof. SIPs have to bear at both ends.”

Coughlin says he often asks suppliers to deliver oversized SIP panels to the job site, making it easier for him and his team to cut them to size at the time of installation.

“We’ll cut them on site because it will go together more quickly,” Coughlin said. “You get involved with some compound cuts. The thing with the panels is that, even on a simple roof job, we’ll take three or four panels together on the ground and we’ll call it a pick. You have to have a flat area to do this on a job, to put all the panels together. Sometimes the pick is just giant.”

Johnson said builders can also face challenges inherent to the difficulty of keeping ICFs straight and parallel.

“How do you get it square, parallel and level?” Johnson said. “You need everything where it needs to be. You can imagine a straight gable roof. That’s not hard to fit. But if you throw in a couple hips and valley to the roof, it can be a real challenge.”

He urged those who are choosing the ICF wall/SIP roof combination for quality or energy-efficiency reasons to keep their designs as simple as possible.

“If what they’re trying to do is modify a Dallas or Memphis mansion into an ICF panel house, it probably isn’t going to work,” Johnson said.

But what does seem to work is notion that the two kinds of panels can compliment each other and provide energy-efficient homes in the bargain.

“SIPs have never really had that big-dollar backing, so the effect is that you go out on the street and talk to contractors who don’t do a lot of alternative building, and they know more about ICFs than SIPs, and are comfortable with the differences,” Johnson said. “But concrete does not look to be the kind of product that will ever make it big as a roof system, so structural panels are a real complimentary fit.”

The combination is not the least expensive, to be sure. One contractor who just finished building his own house with ICF walls and a SIP roof said the roof came out to $12.30 per square foot on a 3,900-square-foot roof.

But there’s price and then there’s value.

“It’s a real valuable product for quality in terms of price,” Johnson said. “When it comes to structures, people tend to deal with cost as being the number one issue. I’ve never understood why.”