By Dave Gowers

Over the past two years, my office has processed 44 ICF projects, 36 of which were residential. This is a substantial increase compared to previous years, and I believe it is an indicator that ICF construction is being more widely accepted for residential construction than in previous years. With the economy currently being in a downturn, construction activity has slowed across most sectors. That being said, ICF residential construction still remains strong.

ICF is used extensively throughout the construction industry for a variety of projects, and residential construction has seen recent strong growth. The following is a review of why ICF would be a good choice for anyone considering new residential construction.

Building Advantages

One of the huge advantages of ICF over other building methods is that it’s very user-friendly for residential owners/builders. Even if there is a shortage of local ICF installers, a homeowner with some construction background can quickly get up to speed with ICF installation, and perform the installation for themselves. Male or female, young or old, ICF installation can be easily learned from either online sources, hands-on instruction, or a combination of both.

Also, minimal tools are required, compared with wood-framed construction. The basic installation is very straightforward, and bringing in additional skilled labor just for pour days dramatically reduces the build cost.

And for contractor installers who may be facing a shortage of skilled labor in this current labor market, the learning curve to become an ICF installer is much faster than for other trades, which means revenue-earning production work can be taken on in the shortest possible time.

Speed of Construction

Getting a residential project started and weathered in before rains come is always a top priority, especially in wet states such as Oregon and Washington. While sunshine states such as California, Texas, and Florida enjoy many months of dry weather, the wetter states have a much shorter window of dry weather activity. Seeing a wood-framed floor, especially a raised foundation floor, getting soaking wet in a heavy rain is a tragedy, as it then has to thoroughly dry out to eliminate mold. Running continuous heaters and dehumidifiers for a duration is both costly and inconvenient.

ICF construction is frequently built on a mono slab foundation, hence eliminating a crawl space. In addition, it is very possible to install a single story of ICF walls, complete with rebar and concrete, in 14 days or less. Allowing another 14 days to install trusses and roof sheathing, and you have a complete weathered-in structure in 28 days following completion of the foundation.

Design Flexibility

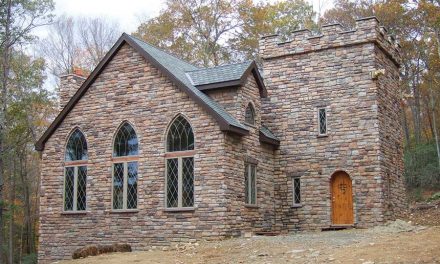

The shear strength of ICF construction is 8 to 10 times that of well-sheared wood-frame construction. This is a major advantage for residential construction, as it allows the architect/designer much more latitude for wide openings, taking advantage of available panoramic views, picturesque vistas, and 180-degree seascapes. And all this is being achieved simultaneously with having an extremely strong building envelope, capable of resisting extreme environmental forces.

Better Living Environment

ICF residential construction provides a better living environment. While the rated R-value of the ICF envelope is measured at approximately R-25, the actual performance will be closer to R-40 due to the effect of the thermal mass of the concrete. Energy savings will be significant, with monthly utility bills being substantially reduced when compared to a well-insulated wood-framed residence.

This will result in long-term savings of operating costs. It is not uncommon for an ICF residence to maintain interior temperatures around 70° F without air conditioning at the same time that exterior temperatures are over 100° Fahrenheit. Similarly, interior temperatures of 70° F can be maintained with minimal heat while exterior temperatures are at freezing.

The reduced sound transference resulting from the thermal mass also results in a quieter living environment. With correctly matched window systems, exterior noise can be virtually eliminated. Vibration is also eliminated, which can be significant in high-wind areas.

Safety and Security

ICF construction is safer and more secure than conventional wood-frame construction. The likelihood of an ICF residence being destroyed by fire, tornado, hurricane, or earthquake is dramatically reduced when compared to the same residence built with wood frame. This gives the homeowner tremendous peace of mind, that their valued possessions, whether they be furniture, antiques, irreplaceable photos, or other mementos, are protected from these all too frequent natural disasters.

ICF Friendly Products

The past several years have seen the introduction of many ICF-friendly accessory products. There are now several readily available brands of acrylic stucco. Examples of these are Stuccomax by Gigacrete, various Dryvit products, U-stucco, and Stucco-flex. All of these products are easily applied directly to the ICF EPS foam and will have outstanding performance with temperature differentials when compared with traditional stucco products.

There are also several readily available brands of ICF-specific hardware. Simpson and Burmon each offer ledger bracket systems, which are considerably more convenient and efficient than setting individual anchor bolts. Burmon also offers an ICF hurricane anchor, an ICF beam hanger, and buck braces to temporarily secure vertical bucks to window and door openings. This product eliminates horizontal lumber buck bracing and is especially preferred for wide door openings so that walkthrough access can be maintained.

For below-ground waterproofing, there are also now several excellent waterproofing systems that can be applied directly to the EPS. Some are peel-and-stick membranes, and others are directly spray-applied products. Sources of these products are Polywall by Polyguard, Rub-R-Wall, Blueskin WP-200 by Henrys, Mel-Rol by Meadows, and Colphene ICF by Soprema.

Conclusion

The net result of all the above is that in both the short term and the long term, ICF construction saves the homeowner money, at the same time providing peace of mind. The operating cost of an ICF structure is also substantially less, leading to very long-term cost savings. Taking all the above into consideration, it is little wonder that ICF construction is finally being seriously considered for a wide range of new building projects, including residential construction.

Dave Gowers

After graduating from UK’s London University 54 years ago, Dave Gowers acquired extensive experience in concrete construction, through diverse commercial, residential, and industrial projects, up to $1 billion in value, in several countries. He is well-versed in concrete formwork and shoring systems, and over the past 18 years has produced structural design solutions for more than 190 ICF projects, both residential and commercial. Dave resides in Southern Oregon with his wife and business partner, Jennifer. Dave holds a PE license in 15 states/territories, is the principal of Dave Gowers Engineering LLC, and is the co-principal of Cascade ICF LLC. Reach him at 541-660-9661 or

dave@dgengineering.com.