While insulated concrete forms (ICFs) are an ideal solution for foundations and basements, there is a misnomer that they are only utilized for those below-grade conditions.

In fact, ICFs can be used above-grade all the way to the roof to enhance their insulation and durability benefits to the end-user.

The Truth Behind ICFs & Whole Home Construction

In the past, many architects and builders believed that ICFs were only suitable for foundations rather than the entire building envelope. In truth, with proper engineering, you can use ICFs to build as high as you’d like with stronger structural integrity than wood-frame or steel-framed construction.

Our code-prescriptive structural reinforcement data can take a residential project up to two stories before requiring additional review by an engineer. In fact, there are many commercial projects that have gone up 10 stories and higher using ICFs for the structural walls. Even these taller structures have maintained disaster-resiliency and can withstand wind speeds upwards of 250 mph (402 kph). That means that even in the face of a tornado or hurricane, ICF buildings will remain intact.

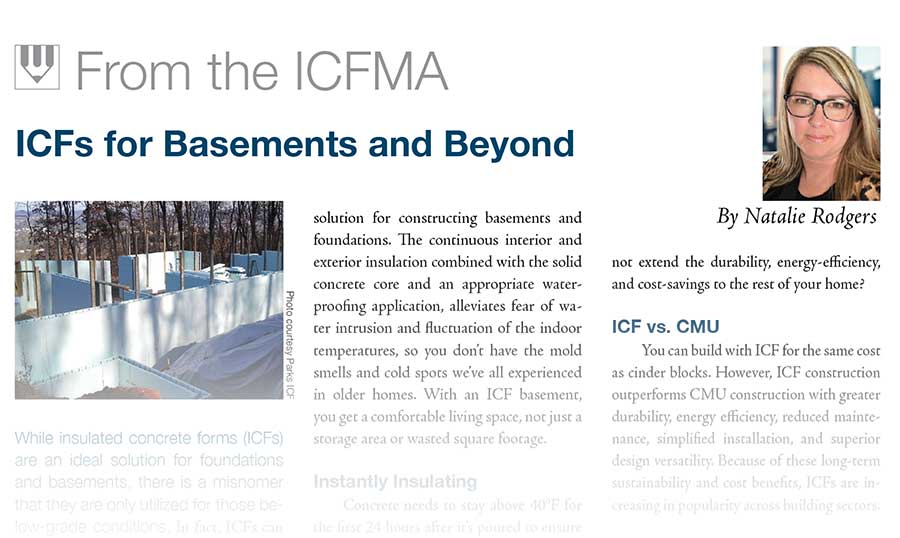

ICF Basements & ICF Foundations

Gone are the days of drafty, musty basements. ICFs are a durable, airtight solution for constructing basements and foundations. The continuous interior and exterior insulation combined with the solid concrete core and an appropriate waterproofing application, alleviates fear of water intrusion and fluctuation of the indoor temperatures, so you don’t have the mold smells and cold spots we’ve all experienced in older homes. With an ICF basement, you get a comfortable living space, not just a storage area or wasted square footage.

Instantly Insulating

Concrete needs to stay above 40°F for the first 24 hours after it’s poured to ensure it cures properly. Maintaining these temperatures can be a challenge in cold fall and winter weather. But the two continuous layers of expanded polystyrene (EPS) in ICFs immediately begin to insulate the concrete poured within the form. This means the concrete will stay at the temperature it was poured at for longer, so it can cure appropriately. In hot weather, this feature can shorten curing time, so your team can complete more projects during a traditionally busy season.

While the concrete is curing, ICF walls can even provide your crew with more protection from the cold and wind compared to wood framing, so you can quickly move on to indoor tasks like wiring or interior framing in safer and more comfortable conditions.

Energy Efficient

If you’re looking for a sustainable home, ICFs are the way to build, with performance that meets or exceeds Passive House standards. Their insulating power reduces air leakage, resulting in decreased utility bills as your heating and cooling systems won’t have to work as hard to keep your interior temperatures consistent. When extreme temperatures hit, the thermal mass of ICF walls helps reduce your footprint on the electrical grid. So, if you’re building an ICF basement, why not extend the durability, energy-efficiency, and cost-savings to the rest of your home?

ICF vs. CMU

You can build with ICF for the same cost as cinder blocks. However, ICF construction outperforms CMU construction with greater durability, energy efficiency, reduced maintenance, simplified installation, and superior design versatility. Because of these long-term sustainability and cost benefits, ICFs are increasing in popularity across building sectors.

ICF vs. Wood

Wood-framed houses typically have wood studs every 16 inches with fiberglass batt insulation in between. The wood studs are areas where the insulation stops, leading to the transfer of thermal properties both hot and cold. These are called thermal breaks or bridges, which work in both directions, where the interior conditioned air can leak out and the exterior air can leak in. This is very inefficient and leads to higher heating and cooling costs to keep mechanicals running to accommodate the air leakage. ICFs, however, have two sides of continuous insulation with a monolithic core of concrete, virtually eliminating thermal bridging. This energy-efficient way of building adds up over time to significant financial savings for the homeowner.

When planning for your next build, think ICFs for their structural durability, versatility, and energy efficiency. Plus, don’t forget ICFs can be used above-grade all the way to the roof.

Natalie Rodgers is the marketing chair of the Insulating Concrete Forms Manufacturers Association (ICFMA, www.icf-ma.org) and Manager of Strategic Learning Programs for Nudura, Part of Tremco Construction Products Group (www.nudura.com).