2023 Specialty Application

Winner

(People’s Choice Winner)

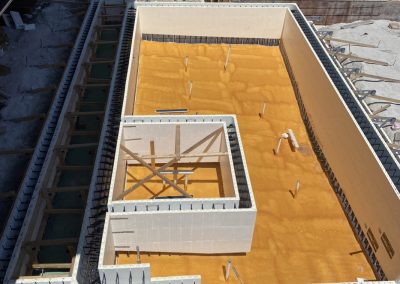

The Condor Infinity-Edge Pool in Springfield, Missouri, was built with Fox Blocks ICFs. The pool was created with a single concrete pour, an EcoFinish, and an integrated clear acrylic wall that allows colored LED lights to escape from the end of the pool and create light effects. The 1,030-square-foot pool is 90 feet long and three-sided, with an ICF wet-edge spillover to create an infinity pool. It took only eight days to install the ICFs for the pool.

Design and Construction

The pool was designed specifically for the homeowners, who wanted a unique feature to complete their new build. Architect Winn Wittman laid out the basic design of the pool and deck area but relied heavily on the pool design expertise of contractor Aaron King to create something truly special. To create a uniquely seamless and integrated appearance, a 15-foot by 4-foot acrylic wall was added, splitting a staircase. “One side of the wall opens to the pool and the other feeds into the lower patios to create a backyard oasis,” says Mike Kennaw, the Fox Blocks representative for the project. “This design was further completed with a built-in hot tub that sits inside of the pool, giving the infinity pool the appearance of an endless flow. The biggest challenge on this project was finding an easy access point for servicing the pool.”

The use of ICF made it possible to place the pool plumbing and electrical in a discreet crawl space below the gutter collection area. The construction of this pool took place during the Covid pandemic, so sourcing was difficult for many items. The engineer specifically required 12-inch core forms in many sections of the pool. Fortunately, Fox Blocks was stocked and readily available, which helped keep the project on track to finish as scheduled.

Another difficulty the team encountered when creating a seamless pool design was ensuring the pool height was even with the main floor of the home. “In order to accomplish this, the team developed a process including engineered fill with more than 100 loads of compact, testing every six inches to maintain structural integrity,” explained Kennaw.

The wet edge was installed so precisely that the pumps function at only 25% power. “This is significantly less than the estimate from Pentair, which included cycling of 900 gallons per minute from

the catch basin into the pool,” Kennaw says. The cost and energy-saving solution would not be possible without the use of ICFs in constructing the pool, which created a perfect foundation for the wet edge install.

The team employed monopour techniques to achieve a solid pool shell, with the floor and walls poured together. This was achieved using Fab-Forms monopour system and bracing, as well as proprietary mix designs, to create the perfect balance between the concrete’s workability and strength.

Design and Architecture

The pool is located behind the house, but the entire design is centered around the unique water features and 20-foot-tall multi-fold glass doors which lead to the main pool. The doors are artistically crafted to take on the appearance of a mirror throughout most hours of daylight. In line with the black inlay behind the pool is a statue which was placed at the perfect height, giving the illusion that it is rising up from the mirrored surface of the pool. The acrylic wall that splits the staircase allows the colored LED lights to escape out from the end of the pool and create a beautiful light washing effect on the lower pool deck areas.

Building a pool with ICF creates the most structurally sound and energy efficient pool with excellent precision and design capabilities. ICF’s properties, in addition to a monopour, result in heating costs that are less than a third of the cost of a comparable gunite pool, even during brutal winters.

The home’s contractor, Cutting Edge Homes, has a successful channel on YouTube, and this project received 24,000 views. As a whole, the channel has nearly 1.5 million views and is devoted primarily to ICF construction and ICF pools. Cutting Edge Homes has been building pools for 15 years, but transitioned to ICF about eight years ago. “Traction received online led to Cutting Edge Homes conducting in-person, four-day training seminars where new and prospective ICF pool builders from around North America come to watch an ICF pool being built,” says Kennaw. “Most of these trainees enter the ICF pool industry immediately upon completion, and these training seminars are a large part of the sudden surge in ICF pool builders, highlighting the benefits and techniques used in ICF construction nationally.”

Cutting Edge Homes with Aaron King is the most innovative and experienced ICF pool builder in the southwest Missouri market, so selecting this team to build their pool was an easy decision for the homeowners. This was one of the team’s first pools with Fox Blocks after many years of experience with another brand. Cutting Edge’s concrete supplier had become a Fox Blocks distributor and asked King to try them out.

Watch a youTube video on this pool: https://www.youtube.com/watch?v=

XkOkf1gfEyc

Project Statistics

Location: Springfield, Missouri

Type: ICF infinity pool

Size: 1,030 sq. ft.

ICF Use: 1,030 sq. ft.

Cost: $550,000

Total Construction: 24 weeks

ICF Installation Time: 8 days

Construction Team

Owner: Venkata Bandaru

General Contractor: Cutting Edge Homes

ICF Installer: Cutting Edge Homes

Form Distributor: Rost Form and Supply, Fox Blocks

Architect: Winn Wittman Architecture

ICF System: Fox Blocks

Fast Facts

- ICF infinity-edge pool with monopour and EcoFinish

- 90-foot-long, three-sided, ICF wet-edge spillover

- Integrated clear acrylic wall supports colored LED light effects

- Pumps function at only 25% power thanks to precise wet edge

- 20-foot multi-fold glass doors create mirror effect

Like what you read?

Yearly Subscriptions Starting @ $30

0 Comments