by Christi Collins

Following few basic safety guidelines will ensure you and your crew stay out of harm’s way on pour day.

Truck-mounted boom pumps are by far the most common way to fill ICF walls and footings. They’re efficient, effective, and affordable. The average ICF residential project, for instance, will see at least three visits from a pump truck. On commercial jobs, it’s not uncommon to have as many as a dozen different trips to the jobsite, with two pumps working simultaneously.

If possible, avoid walking backwards when pouring slabs. The reinforcing mat presents a trip hazard.

These pours, though common, can be dangerous. The combination of scaffolding heights, concrete weight, pipeline pressures, and visibility constraints present ample opportunity for injury.

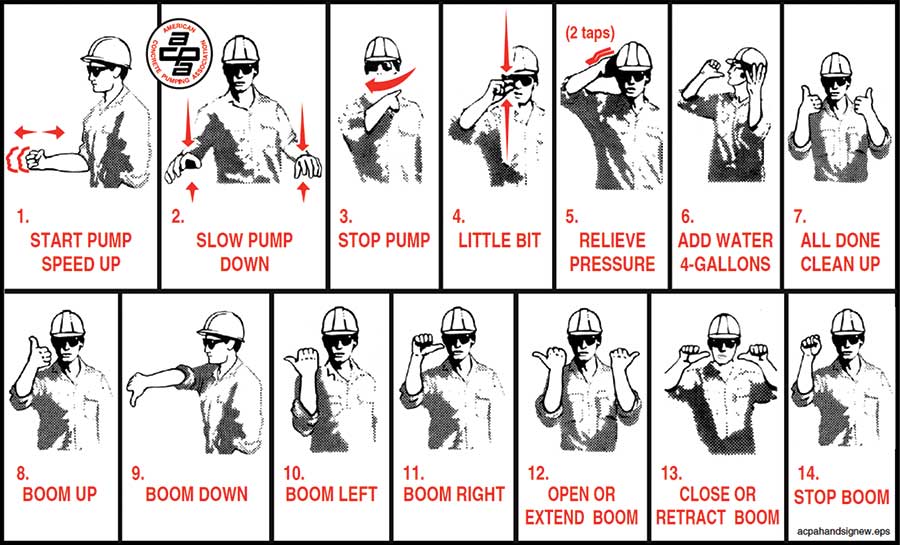

A few years ago, the American Concrete Pumping Association (ACPA) published a booklet specifically for the ICF industry to ensure pour day goes as smoothly as possible. It contains the safety information needed by co-workers to keep them out of harm’s way throughout the course of the day’s work. You should make an effort to see that all persons involved with your pour have access to this information, even if it must be verbally transmitted or translated.

Note that the pump manufacturer’s recommendations supercede any information provided by the ACPA.

On the Ground

Workers near the pump truck must know how to stop the pump and boom. Ask the operator to show you the locations of the emergency stop switches. Personal protective equipment—goggles, hard hat, ear protection, and rubber gloves—are important when working on any concrete pour, and are especially important when working near the concrete pump. Be sure the boots and gloves can resist cement lime burns.

Never put your hands, feet, or any other body part into the water box, concrete valve, or hopper when the hydraulic system is operational or ready to operate.

Avoid standing between the ready-mix truck and the pump truck at all times. Instead, stand to the side, where the driver can see you. When backing in ready-mix trucks, use clear and concise hand signals.

Watch the Boom: Keep an eye on the movements of the boom, even when there are no electrical wires nearby. Alert the operator if he is nearing any obstruction or hazard. If electrical lines are in the vicinity of the area to be poured, it is the position of the ACPA that a spotter shall be employed whose only duty is to observe the movement of the boom and warn the operator if the boom approaches within 20 feet of an electrical wire. This distance is increased to 50 feet if power lines are mounted on steel towers. If the pump or boom were to come into contact with the lines and become energized, anyone in contact with any part of the truck or even near the unit, is at risk of electrocution.

Hopper Levels: Wait until the pump operator gives the “okay” before allowing the ready mix driver to put concrete in the pump hopper. Filling the hopper early can cause the pump to plug.

Do not let the concrete level in the hopper become low enough that you can see the top of the valve mechanism. If air is allowed into the cylinder, it will be compressed, and pressurized air in the line always poses a hazard as it is expelled from the hopper or the delivery pipeline. (See Air in the Line below.)

Never put any solid object in the hopper when the pump is in operation. If foreign material that could create a blockage somehow gets into the hopper, alert the operator to stop the pump. If you can’t get the operator’s attention, push the emergency stop. Do not attempt to remove the material from the hopper or grate while the hydraulic system is ready to work.

Also, make sure the ready-mix driver doesn’t clean his equipment out into the hopper. The extra water will separate the cement and fine sand from the coarse aggregate, which severely weakens the concrete, and also can create a blockage in the pump.

Air in the Line

If air is taken into the material cylinders, take the following steps to minimize the hazard:

- Stop the pump immediately. Hit the emergency stop button if that is the quickest way to stop the pump. There may be an expulsion of compressed air the next time the concrete valve shifts, which can be safely absorbed by filling the hopper with concrete.

- Alert the operator of the problem. It is his job to know the procedures for safely bleeding the compressed air from the delivery system. These procedures may include pumping in reverse for a couple of strokes.

- Persons standing at the discharge end of the delivery line must be warned to move “a prudent and reasonable distance” beyond the reach of the hose until all of the air has been purged and the operator gives you the OK.

- If workers are positioned in high or precarious places, warn them to expect a loud sound as the air escapes the pipeline. Warn them even if they are well away from the discharge to prevent them from falling as a result of being startled by the noise. If possible, allow enough time for them to get to ground level.

- When the pump is restarted, the slowest possible speed should be used until all the air is removed from the pipeline. Don’t assume that the first little air bubble is the end of the compressed air.

Compressed air in the line is always a dangerous situation. Know what can cause this to occur, and how to safely release the pressure.

Note that air will also be present in the line during startup, after moving, when adding or removing hoses, whenever the line has been taken apart or opened for any reason, when waiting for concrete, and when concrete is allowed to drain from the discharge hose.

Similarly, never intentionally introduce compressed air to the system in an attempt to clear a blockage. It is not only unsafe, but futile as well. If pump pressure can’t move the blockage, air pressure won’t either. The operator should know safe blockage removal procedures.

Whenever there is a blockage, the pump must be run in reverse for at least two strokes or the remaining pressure bled off at a safety valve. Use extra caution to ensure the pump and controls are completely powered off and the line is depressurized before opening the pipeline.

On the Scaffold

Workers on scaffolding are exposed to nearly all of the same dangers as the ground crew, with the additional risk factors involved with working on narrow runs of scaffolding.

Guardrails are mandated by OSHA, and easy to install on all major turnbuckle bracing systems. Stay inside the guardrail or use another form of OSHA-approved fall protection.

Workers should also be constantly aware of the boom’s location. Remember, if any part of the pump or boom becomes energized, everyone with any contact with any part of the truck is at risk of electrocution.

Beware of Pressure: In addition to slips, trips, and falls, “hose whip” is another fairly common cause of accidents. This occurs when air is caught in the line, compressed and then suddenly released at the opening, causing the hose tip to whip violently or suddenly spray concrete. Never position any body part between the end of the delivery system and a fixed object (like a hand between the hose tip and the wall forms). Similarly, never allow workers to position themselves between the boom hose and any fixed object like a wall or column.

The chance of a sudden expulsion of concrete (accompanied by chunks of gravel and wet concrete) is why personal protective equipment such as hard hats and eye protection are mandatory.

As already mentioned, air can be introduced into the delivery system in many different ways, but most commonly when restarting the pump.

Also, keep in mind that pipelines wear with each stroke of the pump, and failure of a pipe, clamp, hose, or elbow is always possible. For this and a number of other reasons, spend as little time as possible standing under the boom. (For the same reason, never stand on, sit on, or straddle a pipeline while it’s pressurized.)

Set-Up: Never hang more weight on the boom than it has been designed to hold. If the speed of the concrete free-falling from the tip hose must be slowed, the ACPA recommends using a reducing hose, a smaller discharge hose or a boom configuration to reduce free-fall instead of metal devices attached to the discharge hose.

Specially designed flat hoses are available that are made specifically for eliminating free fall of the concrete and have been tested to burst-pressures sufficient for today’s high pressure concrete pump. Be sure the hose you use meets or exceeds the working pressure rating of the equipment used and is rated for a burst pressure of two times the pump working pressure when new.

In the field, a double elbow or “ram’s horn” is sometimes used to slow the speed of concrete. While the ACPA does not recommend their use, they point out that risks can be somewhat reduced by attaching them between the boom and the boom hose (not the end of the hose). If the hose should whip and hit a worker, any heavy metal device or metal hose end could cause serious injuries or even death.

The Hose man: The hose man should hold the hose securely with both hands, but not hug it. Never try to support the hose tip with the back or shoulders; instead, let the hose hang from the boom.

Try to keep the boom hose no less than two feet above the top of the forms. As the boom moves, the hose tip may come in contact with the forms and be blocked, which could create back pressure and cause the hose to whip.

Do not kink the end of the hose. Kinking will cause the pump to quickly reach maximum concrete pressure, which will likely unkink the hose by force.

The hose man should position himself so that he’s looking the same direction that the pour is progressing. This will allow him to see obstacles and avoid tripping.

The hose man should always stay inside the guardrail or secure himself from falling using some other method. Never tie off to the boom.

Communication: Today’s remote control boom pumps make communication easier than ever before. The operator has the flexibility to get into the best possible position to observe the pour. To avoid confusion and conflicting signals, only one person should signal the pump operator.

Before the pour begins, the hose man, the operator and the spotter must review and agree on the hand signals (See ACPA recommendations below). It is absolutely critical that the pump operator and hose man understand each other.

There’s typically no reason for anyone besides the operator to control the pumping equipment. Even if you are a trained operator and the regular operator has released the controls to you, there must not be more than one operator at a time. (This does not apply to emergency stopping of the pump or boom if there is a need to do so.)

Conclusions

Concrete pump technology is one of the factors that has allowed the ICF industry to enjoy the growth it has seen in the last decade. It’s an economical and efficient means of placing concrete with a few basic rules to ensure the safety of the crew.

- Personal Protective Equipment is a must

- Everyone should be aware of the boom’s location, especially if power lines are nearby.

- Be aware of air pressure in the lines, and the possibility of “hose whip.”

Knowing these safety guidelines will help to ensure a successful and profitable pour on the jobsite.

Christi Collins is Executive Director of the American Concrete Pumping Association. This article is adapted from the 2005 ACPA Safety Manual for ICF Laborers and Placing Crew.