Make sure you have ample space to warehouse the forms, bracing, and other materials dealers are expected to keep in stock.

As the demand for durable, energy-efficient housing and office space has increased, ICF use has skyrocketed. This rapid growth has created business opportunities at all levels of the industry, but many entrepreneurs have found the greatest success in the middle of the supply chain as form distributors and dealers.

“If you’re willing to work hard, and you market accessory products in con-junction with the foam, you’re going to see above average profits,” says Eric Williams, national sales manager at BuildBlock

Building Systems.

Market growth means there’s still plenty of opportunities available. Most companies interviewed said that even with dozens of dealers being trained this year, they are still far short of achieving the market coverage they want. (See the sidebar “Dealerships Available” on the left to discover nearby opportunities.)

Necessary Skills

Dave Watson, national sales manager at American Polysteel, estimates about half of his distributors were formerly contractors. The rest have backgrounds in business, marketing, or sales.

But distributors with other backgrounds can be successful, too. “It’s hard to pinpoint a typical distributor,” says Rhyno Stinchfield, Director of North American Sales for Quad-Lock Building Systems. “I think that of all our distributors, I could only get 4 or 5 to fit into any one classification.”

Many ready-mix concrete suppliers have discovered that an ICF distributorship fits well with their existing business, and has generated significant profits. Some regional building supply centers have experienced similar results. On the other end of the spectrum, many of the most successful dealerships are husband-and-wife teams. “In some ways they [smaller dealers] get more exposure, because they’re out there hustling 24-7,” says Stinchfield.

Quad-Lock recently honored the husband-wife team of Real and Lyne Gagne of Grande Prairie, Alberta, Canada, as their top distributor worldwide. Mike and Robin Hanes, another husband-wife team, have positioned themselves as a leading distributor in the highly competitive Michigan market.

“The most important thing is that they have to understand the industry and have a passion for it,” says Stinchfield. “If a general manager comes and says we’ll take it on, and the salesman don’t have any excitement for the product, it won’t move.”

Williams agrees. “The first and foremost quality is, ‘What have you already done in the ICF industry; are you familiar with the ICFs.”

“This industry is growing but still has tons of work to do to educate builders, homeowners, architects etc., and that takes enthusiasm and passion.” says Sherri Bebee, marketing director at Arxx. “It all comes down to how much fire they have in their belly.”

The ideal distributor is not a category, says Bebee, “He’s a person with a passion for Arxx who proactively communicates that throughout his community…That person could be at a lumberyard, a ready mix company or an entrepreneur.”

Contractors expect building materials to be delivered to the jobsite. This truck is usually busy hauling supplies in the Reno, Nev. area.

Cautions

Many manufacturers say that some of their most successful distributors have a contractor background, but contractors who are considering becoming distributors just to obtain better pricing are in for a shock.

Most of the largest companies won’t let contractors become distributors at all.

The reason? “It’s basic Economics 101,” says Williams. “Contractors have disincentive to sell blocks at a good price to their competitors, and buyers are never sure they are receiving the best value.”

“A contractor will not buy from a contractor,” agrees Stinchfield. “They’ll pay more to buy from a dealer, because they don’t want to give money to their competition.”

“If a contractor is truly interested in becoming a distributor,” says Watson, “we require an exit plan to get out of the [contracting] business or they have to set up a completely separate company.”

Many programs allow the same individual to own both a contracting firm and a distributorship, but all transactions have to be made at ‘arms-length.’ That means you’ll be buying block at the same price as your competitors—and running two separate companies.

What it Takes

Still interested? Regardless of which ICF brand you choose to work with, expectations for new dealers are fairly similar. You will be expected to provide what Williams calls “value added services and materials.” That means inventory, expertise, and outstanding customer service.

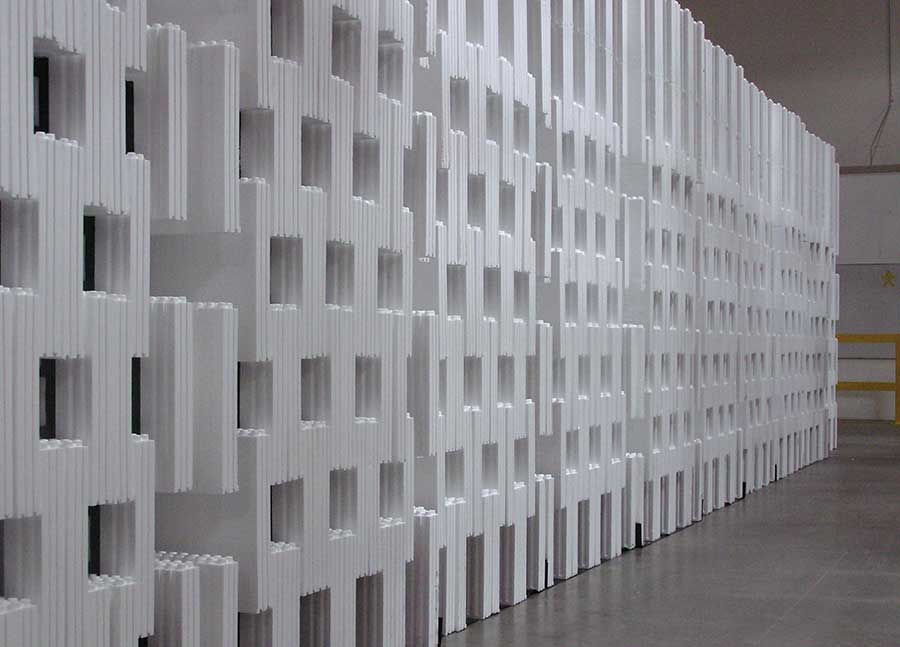

Inventory: A good inventory and warehouse space is basic. “Contractors don’t want to wait for a week for their forms to be shipped across the country,” says Stinchfield. “They expect the dealer to have extra supplies if they’ve miscalculated and come up short, or they’ll want to return stuff if it’s unused and still in good condition.”

Most programs also expect dealers to carry a good selection of accessories as well. Watson explains, “Starting out, we require them to have on hand an inventory of forms, a bracing package, and the accessories used in ICF construction—hot knives, rebar cutters/benders, etc.—or if they don’t stock it, to have it readily available. Ideally they will stock accessory materials, bucks, waterproofing, windows, and exterior finishes. All of those provide additional profit opportunities for the dealer.”

Stinchfield adds, “The more mainstream builders that get into ICFs, the more they’re going to expect that level of service, the same that they’ve been getting from the local lumberyards.”

Technical Support: A second common requirement is the ability to provide local, on-site expertise. “They can’t be a drop-and-run dealer,” says Stinchfield. “Every dealer needs a product champion that knows the product very well. He provides training, visits job sites, and answers whatever questions arise.”

Watson advises small dealerships to separate the roles of business manager and technical expert. “We like our distributors to have installer resource,” he says. “What happens is that a guy will sell two or three projects, but he doesn’t keep the pipeline full. They really need to have somebody else that can visit the jobsites and do the training so that they [the dealer] can concentrate on selling and promoting the business.”

Outstanding Service: “Here’s the bottom line,” says Stinchfield. “Somebody has to act as the dealer. Shipping in from

far way, you never have the right amount. You have to have local training; you have to have a technical expert. Usually they’ll want someone there for the pour and to answer questions as the job progresses. You have to commit to cover the territory and to do so

on short notice.”

Manufacturers also expect a realistic business plan, financial stability, and a commitment to stick to pricing guidelines.

Most manufacturers expect dealers to keep at least one or two truckloads of ICFs on hand at all times.

Program Differences

Form makers generally have high expectations of their

dealers, but they are also very committed to helping them succeed. National sales managers travel thousands of miles every month to teach new distributor seminars and offer individualized help. Companies produce high-quality marketing brochures and technical bulletins. They spend tens of thousands of dollars annually to promote the product through trade shows and national publications like this one.

Every company has also developed specialized tools to help their distributors succeed.

American Polysteel, for instance, has developed specific programs to help distributors market ICFs to commercial contractors, custom home builders, owner-builders, and architect/designers. They also provide an in-house financing program. Like Quad-Lock, they provide dealers with protected territories if they meet certain annual volume requirements.

Arxx does not offer protected territories, but their training and support are legendary. “The Arxx system, Arxx representatives [and] Arxx educational seminars [were] a complete support team that could be relied on,” says Ron Albright of Hanover Concrete, a Pennsylvania ready-mix and ICF dealer.

BuildBlock has devised a complex, five-level system that gives distributors better wholesale prices and other benefits as sales volumes increase.

BuildBlock is one of the few companies that will sell factory-direct to qualified installers. Nearly every other brand requires them to go through the local distributor. “We miss some sales because of that,” says Watson, at Polysteel, “but we’ve made a commitment to the distributor.”

The Process

The process of becoming an ICF distributor is fairly straightforward:

Find out which manufacturers have dealer opportunities in your area and contact those you are most interested in. The sidebar on pg. 26 lists some of the manufacturers currently looking for distributors, with their contact information and website.

The company will probably send you an information packet outlining the company, the ICF industry as a whole, and the requirements for becoming a distributor. If you meet those requirements, fill out the application and send it in.

The company will review your application in a timely manner. They may also conduct a credit check or ask for additional information. If you qualify, the company will contact you to work out your assigned territory, give you pricing details, and sign a distributor agreement.

At some point during this process, usually after the agreement is signed, you will receive in-depth, dealer-specific training to help you get your new business started off right.

That training—combined with business knowledge, construction skills, and the willingness to work hard—is a solid recipe for success. “The amount you make depends on how much effort you put into it,” says Williams.

Opportunities Available

The ICF manufacturers below are currently seeking distributors in select areas:

American Polysteel

www.polysteel.com • 800-977-3676

Amvic Building Systems

www.amvicsystem.com • 877-470 9991

Alam Suleman

All regions in Canada and the US

Arxx Building Products

www.arxxwalls.com • 800-293-3210

Mike Kennaw

All regions in Canada and the US

BuildBlock Building Systems

www.buildblock.com • 866-222-2575

Eric Williams • All enquiries welcome

E-Rated Walls

www.hobbsbuildingsystems.com

515-720-1252

Andrew Hobbs • All regions

Lite-Form Technologies

www.foldform.com

www.liteform.com • www.litedeck.com

800-551-3313 • Wayne Fenton

Select Regions in the U.S. and Canada

Quad-Lock Building Systems

www.quadlock.com • 888-711-5625

Reddi-Wall

www.reddi-wall.com • 586-752-9161

Standard ICF

www.standardICF.com • 800-925-3676

In addition to these ICF manufacturers, many other advertisers in this magazine are also seeking distributors for their products. They can be contacted directly through the phone number on their ad.