2017 SPECIALTY PROJECT BEST IN CLASS

Winner of the “Best Specialty Application” at last year’s ICF Builder Awards, this backyard water feature in Fort Worth, Texas showcases the design flexibility of insulated concrete forms.

Cameron Ware, the Texas ICF distributor who supplied the forms for the project, says, “To put it mildly, this was not your typical ICF project. The project had only one door buck and no windows. Additionally, the walls were deliberately not straight, and also deliberately leaned toward the hill four inches out of plumb.”

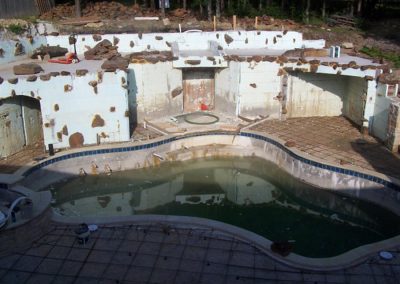

The project has two major components, a 70-foot-long retaining wall and a large waterfall feature with a pumphouse for the equipment.

Ware began with the retaining wall. It’s laid out in a sinuous S-curve to show off the ease of building curves. Ware says, “A significant amount of radius block was utilized for the retaining walls. Most of the retaining walls were over ten feet tall and used 12” core due to their height, but some of the lower areas used eight- and six-inch core.”

In total, the retaining wall used 1,900 sq. ft. of forms. While CMU or poured-in-place concrete could have been used, it was designed from the beginning to showcase ICF. Additionally, Ware says, “It is my belief that ICF retaining walls are superior to conventional poured concrete because the push and pull of the earth is somewhat absorbed or dampened by the foam.”

The water feature and pump room were next, and offered the installers plenty of opportunities to display their craftsmanship. That area features an arched opening, several custom-cut corners, sculptured ICFs to match the look of a natural stone ridge, and even embedded rocks. The area also has an elevated concrete deck. It cantilevers the waterfall out past the rock face into the swimming pool below.

Ware says, “The waterfall was started several years ago and only recently completed.” In fact, when the project was submitted, the concrete pool deck had yet to be installed.

The entire project was largely constructed on weekends. Asked how long the 2,600-sq.-ft. project took to complete, he says “a month of Saturdays.”

Despite the extended timeline, the project has already won advocates for the ICF industry. A number of architects have visited the site, including Ken Taft with Bobby Cox Companies, who toured the site when it was under construction. He has gone on to build a number of ICF structures including a three-story office complex.

The waterfall has sparked interest in others to build more sophisticated versions.

Project Statistics

Location: Ft. Worth, Texas

Type: Retaining Wall and Water Feature

Size: 2,600 sq. ft. (floor)

ICF Use: 2,300 sq. ft.

Total Construction: “a month of Saturdays”

ICF Installation time: 30 days

Construction Team

ICF Installer: Future Stone LLC

Form Distributor: FutureStone, LLC

ICF System: Nudura

Fast Facts

- Curved retaining walls

- Deliberately bantered into hill

- Built to showcase ICF versatility

- Sparked interest in similar projects

Like what you read?

Yearly Subscriptions Starting @ $30

0 Comments