Internal ‘pencil’ vibrators consolidate concrete extremely well, especially when used by an experienced operator.

Good concrete consolidation is essential. Lack of consolidation can cause voids, rock pockets, honeycombing, and poor bonding with the rebar. In extreme cases, improper consolidation can affect the structural integrity of the walls.

On the other hand, excessive vibration can create bulged walls and blowouts.

How much vibration does an ICF wall need, and what is the best way to do it? Good consolidation is a combination of different factors, and vibration is only one of them. Suitable mix design and correct placement technique are critical, but are not discussed in this article. For more information on these topics, see Proper Concrete Placement in the February ’06 issue of this magazine. It’s available online at www.icfmag.com.

Vibration and ICFs is an area that generates significant controversy. ICF-related discussion forums reveal a broad range of opinions and method. In finding an effective solution for you, the principles below should provide general guidelines.

Modern Forms Are Strong

Much of the confusion over how to vibrate ICFs comes from outdated information. Today’s ICFs can withstand internal vibration, and nearly all manufacturers strongly encourage it. But that hasn’t always been the case. As recently as the late 1990’s, some ICF designs did not have the strength to handle adequate vibration. Contractors were advised to use orbital sanders, reciprocating saws with the blade removed, or even to “bang on the blocks with a short length of 2×4.”Unfortunately, these methods do not provide sufficient consolidation. Even more regrettably, these sub-par methods are still being used by some contractors.

Review an up-to-date installation manual or talk to the technical director at your preferred ICF company to get their latest recommendations about consolidation techniques. If these sources reveal that the form will not withstand internal vibration, consider switching to a more modern ICF design. Jobs with inadequate consolidation not only damage your reputation, but that of the entire industry.

Follow Published Guidelines

In 2003, the Portland Cement Association (PCA) conducted an in-depth study of concrete consolidation and ICFs. They tested flat panels with 4- and 6-inch cores, as well as a screen grid and waffle grid ICFs. Panels with corners and lintels were also tested. Test sections were filled with low- (3”), medium- (6”) and high-slump (8”-10”) concrete and vibrated with wood blocks, saws, sanders, and internal vibrators. They also filled test panels with a self-consolidating concrete (SCC).

In every case, walls filled with low-slump mixes had poor consolidation, regardless of the technique used. “External mechanical vibration using a hammer, reciprocating saw, or orbital sander did not significantly improve the consolidation of concrete in ICF walls…” the report states.

On the medium slump panels, external vibration scored slightly better, but not nearly as well as those that used an internal vibrator. High-slump concrete and SCC achieved adequate consolidation with minimal vibration.

The entire report, titled RD-134 Concrete Consolidation and the Potential for Voids in ICF Walls, is available for download from our website, or hard copies can be purchased from the PCA bookstore.

Additional guidelines for concrete consolidation are available under the American Concrete Institute’s ACI 318, and from various concrete vibrator manufacturers.

Internal Vibration Requires Trained Operators

The PCA report mentioned above concluded, “Internal vibration was found to provide adequate consolidation for concrete with a slump of 6 inches or greater… As an alternative to internal vibration, adequate consolidation also was achieved through the use of a flowable, high-slump concrete.”

Fred Oswald, president of Oztec Industries, says it’s usually more cost-effective to vibrate conventional mix designs, since superplasticizers and SCC cost considerably more per yard.“And the forms have to be almost watertight to hold the mix,” he adds.

“We recommend using a 3/4 inch diameter head for most ICFs,” Oswald says, “although it depends on the width of the form and the slump of the concrete. A stiff mix with a 4-inch slump needs a bigger head.” Even more important than correct equipment, though, is having a trained operator.

The vibrator should be inserted vertically into the mix, then slowly withdrawn. Vibrators work by allowing air to float up and out of the concrete, so the tip should not be withdrawn faster than the air can move upward, about 3 inches per second. If the wall is poured in multiple lifts, the vibrator tip should go deep enough to penetrate 3 to 6 in. into the previous layer.

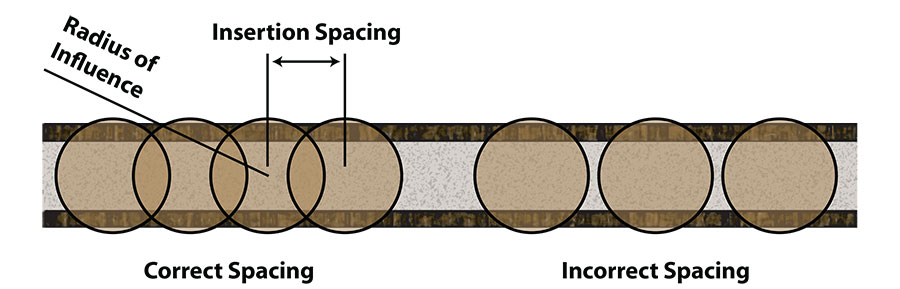

The vibrator has a “zone of influence” where consolidation is occurring. For proper consolidation, the operator needs to ensure the zones of influence overlap successively so that all areas of the concrete are properly consolidated.“It has to be done very systematically,” Oswald states.

Pay Attention to Corners and Lintels

Ironically, corners and lintels—the areas that need the most strength—are where poor consolidation is most likely to occur. That’s because these are the areas where reinforcing steel is most congested—and ICF forms are at their weakest. But these areas need more vibration, not less. Add extra bracing as needed; each form manufacturer has developed instruction on how to minimize corner movement, using a combination of plywood, zip ties, strapping tape, or additional bracing. Set an additional brace along each side of each window opening as well.

Finally, note that the area below each window buck needs to be filled and vibrated separately.

Sizing the Vibrator

The PCA research on consolidation used a single internal vibrator. It had an amplitude of .08 mm and a ¾ inch head, giving an effective zone of influence six inches in diameter. Inserting the vibrator twice per linear foot of wall is tedious, and in many cases impractical. While no formal research has been done, here’s what those in the field say:

“A pencil [vibrator] doesn’t really get the job done,” a New York builder admits, “I use a 1 3/4” square head. Never had a problem with a blowout. The use of pencil vibrators started long ago because many of the old forms couldn’t take anything bigger. I’ve vibrated jobs with 2 1/2” a couple of times. Kinda increases the pucker factor, but I’ve had no problems.”

Eldon Howe, who has worked with ICFs for years in Michigan, says, “I’m using a 1.8 oz motor and a 1.5” head for a regular six-inch core. I’ve used a 1.5” head on a 14-foot whip with a 1.9 oz. motor [but] it seems a little much in a 6” wall. I believe it will work well in an eight-inch or thicker wall, though.”

Internal Vibration Requires Trained Operators

The PCA report mentioned above concluded, “Internal vibration was found to provide adequate consolidation for concrete with a slump of 6 inches or greater… As an alternative to internal vibration, adequate consolidation also was achieved through the use of a flowable, high-slump concrete.”

Fred Oswald, president of Oztec Industries, says it’s usually more cost-effective to vibrate conventional mix designs, since superplasticizers and SCC cost considerably more per yard.“And the forms have to be almost watertight to hold the mix,” he adds.

“We recommend using a 3/4 inch diameter head for most ICFs,” Oswald says, “although it depends on the width of the form and the slump of the concrete. A stiff mix with a 4-inch slump needs a bigger head.” Even more important than correct equipment, though, is having a trained operator.

The vibrator should be inserted vertically into the mix, then slowly withdrawn. Vibrators work by allowing air to float up and out of the concrete, so the tip should not be withdrawn faster than the air can move upward, about 3 inches per second. If the wall is poured in multiple lifts, the vibrator tip should go deep enough to penetrate 3 to 6 in. into the previous layer.

The vibrator has a “zone of influence” where consolidation is occurring. For proper consolidation, the operator needs to ensure the zones of influence overlap successively so that all areas of the concrete are properly consolidated.“It has to be done very systematically,” Oswald states.

Pay Attention to Corners and Lintels

Ironically, corners and lintels—the areas that need the most strength—are where poor consolidation is most likely to occur. That’s because these are the areas where reinforcing steel is most congested—and ICF forms are at their weakest. But these areas need more vibration, not less. Add extra bracing as needed; each form manufacturer has developed instruction on how to minimize corner movement, using a combination of plywood, zip ties, strapping tape, or additional bracing. Set an additional brace along each side of each window opening as well.

Finally, note that the area below each window buck needs to be filled and vibrated separately.

Sizing the Vibrator

The PCA research on consolidation used a single internal vibrator. It had an amplitude of .08 mm and a ¾ inch head, giving an effective zone of influence six inches in diameter. Inserting the vibrator twice per linear foot of wall is tedious, and in many cases impractical. While no formal research has been done, here’s what those in the field say:

“A pencil [vibrator] doesn’t really get the job done,” a New York builder admits, “I use a 1 3/4” square head. Never had a problem with a blowout. The use of pencil vibrators started long ago because many of the old forms couldn’t take anything bigger. I’ve vibrated jobs with 2 1/2” a couple of times. Kinda increases the pucker factor, but I’ve had no problems.”

Eldon Howe, who has worked with ICFs for years in Michigan, says, “I’m using a 1.8 oz motor and a 1.5” head for a regular six-inch core. I’ve used a 1.5” head on a 14-foot whip with a 1.9 oz. motor [but] it seems a little much in a 6” wall. I believe it will work well in an eight-inch or thicker wall, though.”

Consolidation Tips

• Start with a good mix. Most recommend a slump of at least 6 inches.

• Place material intelligently. Use a pump truck. A reducing hose can reduce splatter and increase efficiency.

• Brace corners and lintels well and vibrate them thoroughly.

• Consolidate carefully within the manufacturer’s guidelines.

• Internal vibration by a trained operator has proven most successful.