2022 MultiFamily Low-Rise

Winner

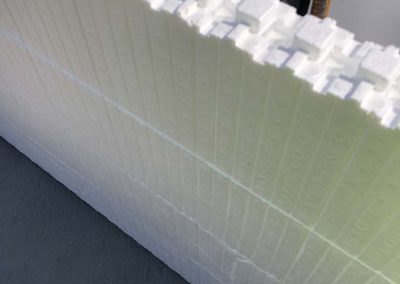

These townhomes in Johnston, Rhode Island, outperform an identical wood prototype in energy consumption by 50%. That’s just one of the benefits that the builders found by using ICFs on this $22 million project. The builders estimate that each of 36 fourplexes was built two months faster using ICF, and at a savings of nearly $50 per square foot with ICF versus the cost of typical wood construction. The project is just under 300,000 square feet, and 91% of exterior walls were built with Amvic ICFs. All 82,620 square feet of fire separation walls between townhomes are ICF. A neighborhood clubhouse on the same development was also constructed with ICF. The final result is an elegant, simple design that delivers superior sound control and fire safety for the new occupants that will also deliver lower long-term maintenance costs.

“The greatest challenge behind this project was to convince a well-established developer known for constructing with wood for more than 30 years to make the switch to Insulated Concrete Forms,” says Laura Catalan, the director of marketing for Amvic. The key was to create an efficient design and streamlined process to allow the townhomes to be built for less than the cost of wood construction.

Careful Collaboration

Catalan explains that it took careful collaboration between the architect and the builder to facilitate a design that allowed for a fast assembly process. The spacing and the spans required for the structure were carefully coordinated to work alongside other building systems in order to keep costs down and minimize complexities. It required “creativity and genius” she says, and an ongoing management of the daily construction operations and strong relationships with material suppliers.

The builder had a pre-existing relationship with the owner of this project and the builder was the key in convincing the owner to proceed with ICF for this project. The builder and architect chose Amvic because of the higher density of its EPS foam and the spacing of the ties at 6 inches on center.

Another challenge was that the in-house construction team learned how to install ICFs for the first time, but they were trained on-site and showed quick progression. By the time the final fourplexes were done, the team were adept ICF installers. Another major challenge was that the site needed significant prep. The site was large, sloped, and had a layer of solid rock that needed to be removed, crushed, and processed to become fill material for the base layer.

Assembly Line Process

Despite all this, the team developed an efficient assembly line process in which up to four structures would be assembled at the same time at different stages of the ICF install process. “On average, a new ICF structure would be poured every other week over a period of 114 weeks,” Catalan says. Plumwall bracing was used for the support. Due to the simplicity of the design, craftsmanship was of utmost importance as any imperfections would be highly visible.

Sustainable, Approachable Design

The size of each unit was carefully considered to avoid requiring any additional needs like bracing, yet still delivering a comfortable three-bedroom unit. The final height of the ICF was dictated by the coursing of the ICF forms along with the dimensions of a standard gypsum board to ensure there was no additional labor, cutting, and waste during construction to accelerate the construction process.

Due to the circumstances of how this project transitioned from wood to ICF, there was already an existing fourplex structure built with wood of the same design on this property. Once the first group of new ICF fourplexes was added to the property, a rare opportunity arose to compare two similar designs built side by side with completely different building systems. “When comparing the electricity bills between the two structures, the wood framed townhomes have an average electrical bill of $470 whereas the adjacent ICF structure has an average electrical bill of $250,” says Catalan. “Moving forward, this will become a key case study to use within the industry to catapult Insulated Concrete Forms to the forefront. In addition, this energy comparison combined with the cost effectiveness in getting the ICF structures built is what mainly convinced the owner that there is no better way to build.”

A Clear Indicator

This project is a clear indicator that concrete construction can be achieved faster and cheaper than wood construction. When the project initially started, the first group of fourplexes were built at an outstanding rate of $62.50 per square foot, which increased to $80 per square foot after adjusting for changes/increases in the cost of material, labor, etc. with a build that completed during the early months of the Covid pandemic. This project convinced the owner to build multiple new high-end homes in the same region with ICF. In addition, plans are already underway for another new major residential development in Florida that will consist of a total of 250 new residential units that will be built with only concrete construction to achieve the desired hurricane resistance. The owner is now convinced there is no better way to build.

Project Statistics

Location: Johnston, Rhode Island

Type: Townhomes

Size: Approx. 290,000 sq. ft.

ICF Use: 245,412 sq. ft. (not including ICF clubhouse)

Cost: $21.6 million

Total Construction: 114 weeks

ICF Installation Time: 480 days

Construction Team

Owner/Developer: Charda Properties LLC

General Contractor: Network Management Construction Corp.

ICF Installer: In-house ICF installation within the GC team

Form Distributor: Amvic

Architect: Architectura SA Inc.

ICF System: Amvic

Fast Facts

- One of the largest townhome mass ICF developments in the US

- Nearly 290,000 sq. ft. of new residential housing

- Designed and managed to be cost-effectively built

- First-time ICF project for developer who’s built for over 30 years

- A total of 144 residential units in 36 separate structures

- Outperforms an identical wood prototype in energy consumption by 50%

Like what you read?

Yearly Subscriptions Starting @ $30

0 Comments